INTRODUCTION OF FOUNDRY PRO

A SOFTWARE BASED ON A TOUCHSCREEN CONCEPT, FOUNDRY PLUS IS THE MOST COMPREHENSIVE SOLUTION FOR CAST IRON INDUSTRIES. THE SOFTWARE IS USED TO ESTIMATE NODULES, FLAKE SIZE AND THE CLASS AND NUMBER FROM 1 TO 8 AS PER ASTM, JIS AND ISO STANDARDS. FURTHERMORE, THE SOFTWARE INCLUDES VARIOUS TEMPLATES FOR REPORTING.

OPTION TO GET ANALYSIS REPORT BASED ON ASTM 247-67 OR ISO 945_1 STANDARDS.

NODULES TOUCHING BOUNDARIES ARE EXCLUDED IN ANALYSIS.

ARTEFACTS LESS THAN 10 MICRONS ARE EXCLUDED IN ANALYSIS.

NODULES ARE SEPARATED FROM NON-NODULES ON PREDEFINED SPHEROIDICITY. THE NODULES/FLAKES FORM (DESIGNATED BY ROMAN NUMBERS I TO VI) AND SIZE (DESIGNATED BY ARABIC NUMBERS 1 TO 8) ARE REPORTED.

THE FLAKE OCCURRING IN CAST IRON IN THE FORM I, ARE REPORTED ON THE BASIS OF TYPE OF DISTRIBUTION (DESIGNATED BY CAPITAL LETTERS A TO E) AND ON THE BASIS OF ORIENTATION.

THE PERCENTAGE OF PEARLITE IS CALCULATED BY EXCLUDING THE GRAPHITE AREA.

THE MATRIX OF PEARLITE, FERRITE, GRAPHITE AND CARBIDE ARE REPORTED IN ETCHED SAMPLE.

REPORT IS GENERATED WITH SPECIFIC INTERNATIONAL STANDARDS CHOSEN BY THE USER.

F% IS REPORTED IN JIS METHOD

MODULES OF FOUNDRY PRO

SOME OF THE MAJOR MODULES IN FOUNDRY PRO ARE AS FOLLOWS:

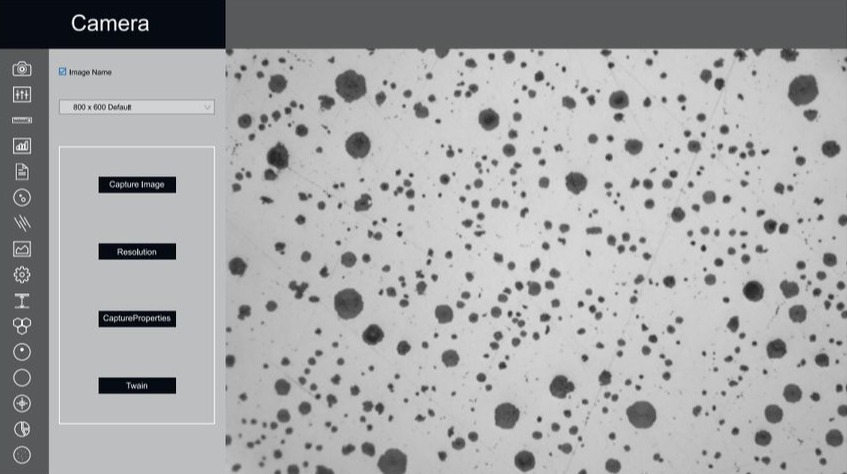

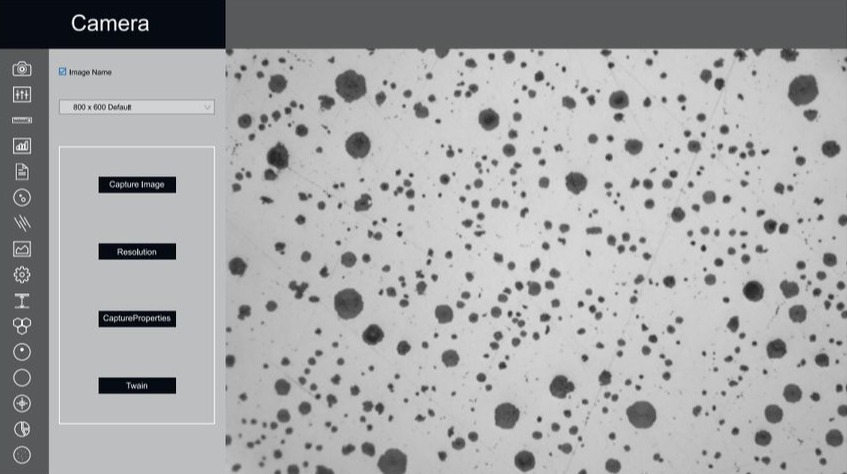

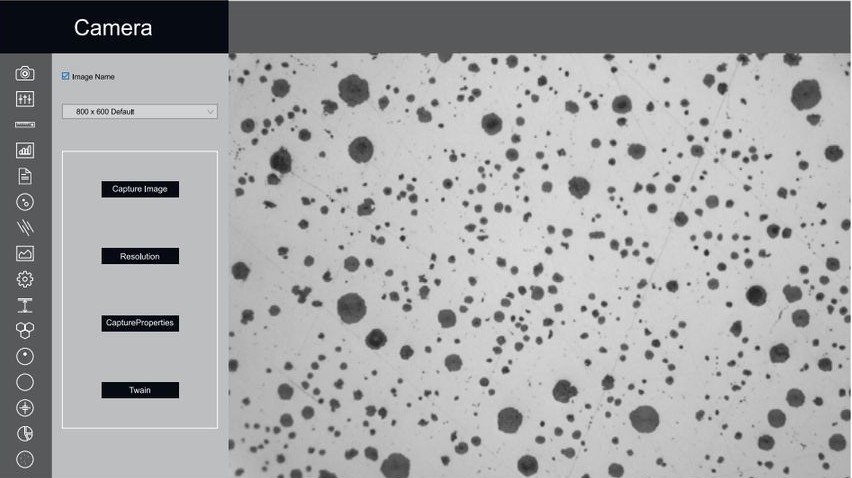

CAMERA

ONE CAN SELECT DIFFERENT DISPLAY/CAPTURE SIZES ALONG WITH OTHER SETTING LIKE WHITE BALANCE, BRIGHTNESS, CONTRAST, HUE, SATURATION CAN BE CHANGED ON LIVE DISPLAYED IMAGE. ONCE ALL SETTING ARE DONE, IMAGE CAN BE CAPTURED IN APPROPRIATE FOLDER FOR APPROPRIATE ANALYSIS

CALIBRATION

CALIBRATION SHOULD BE PERFORMED ON ALL THE OBJECTIVES OF THE MICROSCOPE, WHERE DIGITAL CAMERA IS INSTALLED. CALIBRATION SHOULD BE PERFORMED ONLY WHEN ALL HARDWARES ARE FINALLY FIXED. IN CASE OF READJUSTMENTS OR REPLACEMENT OF ANY PART, CALIBRATION SHOULD BE DONE AGAIN

MEASUREMENT

WITH THE MEASUREMENT MODULE ONE CAN OBTAIN MEASUREMENT ON MANUALLY DRAWN LINES ON TRACES, SHAPES OR BY OUTLINING AN OBJECT WHICH CANNOT BE ACCUMULATED AND LOGGED ON TO THE RESULTS WORKSHEET FROM WHERE THEY CAN BE STORED TO A FILE, PRINTED OR TRANSFERRED TO SPREAD SHEET FOR FURTHER ANALYSIS OR STATISTICS

CARBIDE

IRON CARBIDE OR CEMENTITE IS AN INTERMETALLIC COMPONENT OF IRON AND CARBON. WHILE IRON CARBIDE AS PRESENT IN MOST STEELS AND CAST IRON, IT IS PRODUCED AS RAW MATERIAL IN THE IRON CARBIDE PROCESS, WHICH BELONGS TO THE FAMILY OF ALTERNATIVE IRON MAKING TECHNOLOGY

SG IRON

SG CAST IRON OR NODULES ARE ALSO CALLED DUCTILE IRON OR SPHEROIDAL GRAPHITE IRON. NODULES CAST IRON ARE PRODUCE FROM GRAPHITE DURING SOLIDIFICATION. DUCTILE IRON ANALYSIS MODULE PROVIDES A CHANCE TO ANALYZE AN IMAGE ON THE BASIS OF ASTM A-247-67, ISO-945-1

GRAY IRON

GREY IRON OR GREY CAST IRON IS A TYPE OF CAST IRON THAT HAS A GRAPHITIC MICRO STRUCTURE. GREY IRON ANALYSIS MODULE PROVIDES A CHANCE TO ANALYZE AN IMAGE ON THE BASIS OF ASTM A-247-67, ISO 945-1

REPORT DATA

ALL REPORTS ARE SAVED IN THE FOLDER AND CAN BE RETRIEVE ANYTIME IN FUTURE.

GALLERY

OUR FOLDERS ARE AVAILABLE TO VIEW ANY CAPTURED IMAGES. THE FOLDERS ARE: 1. NODULARITY | 2. FLAKE | 3. CARBIDE | 4. LINE MEASUREMENT

SETTINGS

THE MODULE SETTING IS DESIGNED TO SET VARIOUS PARAMETERS FOR FIRST TIME WHEN SOFTWARE IS INSTALLED. THE SETTING OPTIONS ARE AVAILABLE TO CHOOSE ISO/ASTM STANDARD CALIBRATION, SETTING IN REPORT FORMAT, SETTING OF VARIOUS PARAMETER ON PRINTED IMAGE IN REPORT. ONCE ALL SETTINGS ARE DONE, YOU NEED ONE BUTTON CLICK FOR ALL ANALYSIS. ALL SETTINGS ARE STORED TILL YOU CHANGE THEM IN FUTURE. DO NOT CHANGE THEM IN ROUTINE, IT IS NOT NECESSARY.

CAMERA

ONE CAN SELECT DIFFERENT DISPLAY/CAPTURE SIZES ALONG WITH OTHER SETTING LIKE WHITE BALANCE, BRIGHTNESS, CONTRAST, HUE, SATURATION CAN BE CHANGED ON LIVE DISPLAYED IMAGE. ONCE ALL SETTING ARE DONE, IMAGE CAN BE CAPTURED IN APPROPRIATE FOLDER FOR APPROPRIATE ANALYSIS

CALIBRATION

MEASUREMENT

WITH THE MEASUREMENT MODULE ONE CAN OBTAIN MEASUREMENT ON MANUALLY DRAWN LINES ON TRACES, SHAPES OR BY OUTLINING AN OBJECT WHICH CANNOT BE ACCUMULATED AND LOGGED ON TO THE RESULTS WORKSHEET FROM WHERE THEY CAN BE STORED

THIS IS LOOK OF SOFTWARE

DUCTILE IRON/NODULARITY

DUCTILE IRON, ALSO KNOWN AS DUCTILE CAST IRON, NODULAR CAST IRON, SPHERIODAL GRAPHITE IRON & SG IRON IS A TYPE OF GRAPHITE RICH CAST IRON. WE USE IMAGE PROCESSING ALGORITHMS LIKE SEGMENTATION USING GLOBAL THRESHOLDING, BOUNDARY DETECTION AND ARTIFICIAL NEURAL NETWORK. NODULES TOUCHING BOUNDARIES ARE EXCLUDED IN ANALYSIS. ARTIFACTS LESS THAN 10 MICRONS ARE EXCLUDED. NON–NODULES ARE SEPARATED FROM NONNODULES ON PREDEFINED SPHERODICITY. FOR ANALYSIS OF SG IRON, WE COMPUTE QUALITY PARAMETERS SUCH AS NODULES COUNTS, NODULE SIZE (DESIGNATED BY ARABIC NO. 1 TO 8), NODULE FORM (DESIGNATED BY ROMAN NUMBER I TO VI). ALL ANALYSIS ARE DONE WITH SINGLE BUTTON PUSH.

IN THE SECOND STEP, ETCHED SAMPLES ARE ANALYSED. THE SOFTWARE AUTOMATICALLY CALCULATES THE PERCENTAGE GRAPHITE, PEARLITE ONCE THE ANALYSIS COMPLETED. ALL DATA OF NON-ETCHED AND ETCHED SAMPLE IS APPENDED INTO A RESULTS SPREADSHEET DIRECTLY WITH IN THE IMAGE ANALYSIS SOFTWARE.

REPORTS CONTAINING RELEVANT ANALYSIS DATA AND ASSOCIATED IMAGES ARE GENERATED WITH ONE BUTTON PUSH.

DUCTILE IRON/NODULARITY

GRAY IRON/GRAPHITE FLAKES

GRAY IRON OR GRAY CAST IRON IS THE GRAPHITE FLAKES STRUCTURE THAT IS CREATED DURING THE COOLING PROCESS. IT IS NAMED AFTER THE GRAY COLOR OF THE FRACTURE ITS FORMS, WHICH IS DUE TO THE PRESENCE OF GRAPHITE. THE APPLICATION MEASURES GRAPHITE LENGTH IN GRAY IRON. THE SHORTER THE A TYPE GRAPHITE FLAKES, THE HIGHEST THE STRENGTH AND BETTER THE DUCTILITY. THE AUTOMATIC, ONE BUTTON COMPUTER PROGRAM QUANTITATIVELY ANALYSES THE GRAPHITE LENGTH IN METALLOGRAPHY. THE GRAPHITE SIZES ARE REPORTED IN 1-8 CLASSES OF SIZE ACCORDING TO ASTM 247-67 OR ISO 945 -1 STANDARDS. IT CATEGORIZES GRAPHITE FLAKES FROM NAMELY TYPE A,B,C,D & E IN MICROSTRUCTURE SAMPLE ON THE BASIS OF ORIENTATION

THE PERCENTAGE OF PEARLITE IS CALCULATED BY EXCLUDING THE GRAPHITE AREA. THE MATRIX OF PEARLITE , FERRITE , GRAPHITE ARE REPORTED IN ETCHED SAMPLE .

REPORT IS GENERATED WIT SPECIFIC INTERNATIONAL STANDARDS CHOSEN BY THE USER

CARBIDE BANDING

IRON CARBIDE OR CEMENTITE IS AN INTERMETALLIC COMPONENT OF IRON AND CARBON. WHILE IRON CARBIDE AS PRESENT IN MOST STEELS AND CAST IRON, IT IS PRODUCED AS RAW MATERIAL IN THE IRON CARBIDE PROCESS, WHICH BELONGS TO THE FAMILY OF ALTERNATIVE IRON MAKING TECHNOLOGY

SETTINGS

THE MODULE SETTING IS DESIGNED TO SET VARIOUS PARAMETERS FOR FIRST TIME WHEN SOFTWARE IS INSTALLED. THE SETTING OPTIONS ARE AVAILABLE TO CHOOSE ISO/ASTM STANDARD CALIBRATION, SETTING IN REPORT FORMAT, SETTING OF VARIOUS PARAMETER ON PRINTED IMAGE IN REPORT. ONCE ALL SETTINGS ARE DONE, YOU NEED ONE BUTTON CLICK FOR ALL ANALYSIS.

ALL SETTINGS ARE STORED TILL YOU CHANGE THEM IN FUTURE. DO NOT CHANGE THEM IN ROUTINE, IT IS NOT NECESSARY

IF CLICK ON SETTINGS ICON, NEW UI WILL OPEN. THE PLATFORM HELP YOU TO DECIDE THE SHORTCUTS OF YOUR WORKING. IF YOU CHOOSE ANY OF RADIO BUTTON CORRECTLY, YOUR WORKING WILL HAVE NO SCOPE FOR MISTAKE AND SOFTWARE WILL BE ONE BUTTON WORKING

1. REPORT TYPE

OPTIONS ARE AVAILABLE TO GET REPORT EITHER IN ASTM OR ISO FORMATS. CHOOSE ANY OF THEM, THIS WILL BE AUTOMATICALLY BE IN DEFAULT SETTING TILL YOU MODIFY IN FUTURE.

2. SET DEFAULT USE

OUR SOFTWARE GIVE A CHOICE TO WORK EITHER ON LIVE DISPLAY IMAGES OR YOU CAN CAPTURE FIRST ALL IMAGES AND WORK ON THEM LATER.

• IT MEANS YOU WANT TO WORK ON LIVE IMAGES. • THIS IS FOR WORKING ON STORED / CAPTURED IMAGES

3. SELECT CALIBRATION

CHOOSE CALIBRATION WHICH ARE AVAILABLE IN STORED DATA. USUALLY WE DO ALL WORK ON 100X OBJECTIVE IN CAST IRON.

4. SET 100 MICRON LINE

IF YOU NEED SCALE BAR ON IMAGE CHOOSE THE FOURTH OPTIONS AVAILABLE:

• TO SHOW BOUNDARY CLICK IT IF YOU WANT TO SEE CONTOUR AROUND THE GRAPHITE.

• CLICK ON SHOW NUMBER IF YOU WANT TO DISPLAY COUNTING ON GRAPHITES

5. SET GALLERY PATH

GALLERY PATH IS SET BY DEFAULT. BUT IF YOU NEED TO CHANGE THIS PATH, YOU CAN DO NECESSARY CHANGES.

6. SG IRON

VARIOUS OPTIONS ARE AVAILABLE TO SHOW DIFFERENT PARAMETERS ON NODULES. CHOOSE IT IF YOU REQUIRE OTHERWISE CONTOUR IS CREATED BY DEFAULT

7. ASPECT RATIO

THIS IS USUALLY FIXED. BUT CHANGE ONLY IF REQUIRED

• REPORT WITH CHEMICAL COMPOSITION AND PHYSICAL ANALYSIS PROPERTIES COMPOSITION.

• REPORT WITHOUT CHEMICAL & PHYSICAL PROPERTIES

REPORTING DATA

REPORT IS AVAILABLE IN THIS MODULE FOR PREVIEW BEFORE PRINT OR IF PRINT IS NOT REQUIRED.

GALLERY

FOUR FOLDERS ARE AVAILABLE TO VIEW ANY CAPTURED IMAGES. THE FOLDERS ARE:

1. NODULARITY

2. FLAKE

3. CARBIDE

4. LINE MEASUREMENT

REPORT

THE FLAKE OCCURRING IN CAST IRON IN THE FORM I, ARE REPORTED ON THE BASIS OF TYPE OF DISTRIBUTION (DESIGNATED BY CAPITAL LETTERS A TO E) AND ON THE BASIS OF ORIENTATION.

THE PERCENTAGE OF PEARLITE IS CALCULATED BY EXCLUDING THE GRAPHITE AREA.

THE MATRIX OF PEARLITE, FERRITE, GRAPHITE AND CARBIDE ARE REPORTED IN ETCHED SAMPLE.

REPORT IS GENERATED WITH SPECIFIC INTERNATIONAL STANDARDS CHOSEN BY THE USER.

No technical specifications available for this product.