Flexible & Compatible: Works with various cameras, microscopes, and capture cards.

Supports Multiple Formats: BMP, JPEG, TIFF, PNG, GIF, PSD – analyze any image type.

Real-Time Live Image Capture: Capture and analyze live images on the same platform.

Seamless Data Integration: Easily export graphs and charts to MS Word, Excel, or any Windows-based software.

Comprehensive Hardness Testing: Supports Vickers, Brinell, and Knoop tests—manual and automatic modes available.

INTRODUCTION OF HARDNESS PRO

It is new generation image analysis software, meant for scientist to do analysis in the simplest way. It is a single screen Window based system. The system is flexible and independent to adopt capture cards, cameras and microscopes.

It can handle both gray monochrome (8 bit) and color (24 bit) images. Multiple images of any size can be opened and display on the screen for analysis or comparison. The software supports most common formats like BMP, JPEG, TIFF, PNG, GIF and PSD. Live images also can be observed and capture on the same platform. Since the system is made in Windows environment, graphs and charts display on the monitor can be quickly transferred into other Windows based programs like MS Word, MS Excel or any other commercial Windows based software for using reports and presentations.

CAMERA

One can select different display/capture sizes along with other setting like white balance, brightness, contrast, Hue, Saturation can be changed on live displayed image. Once all setting are done, image can be captured in appropriate folder for appropriate analysis.

CALIBRATION

Calibration should be performed on all the objectives of the microscope, where Digital Camera is installed. Calibration should be performed only when all hardwares are finally fixed. In case of readjustments or replacement of any part, calibration should be done again.

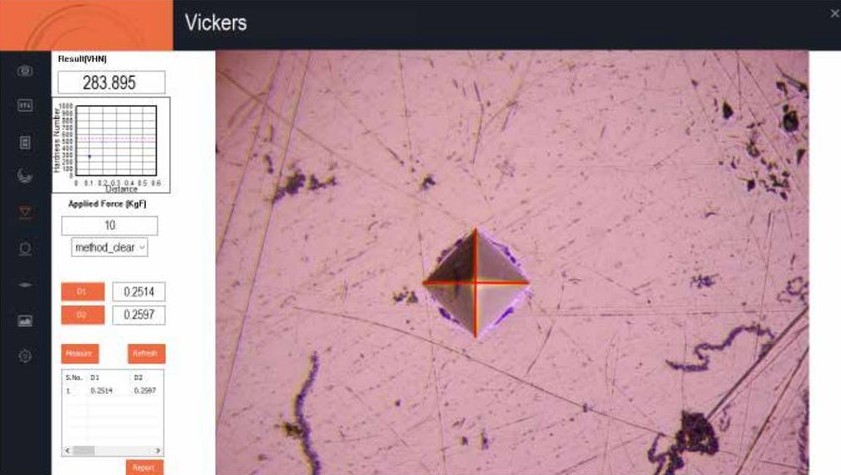

MANUAL VICKERS

The Vicker hardness test is an indentation hardness test in which a square-based diamond pyramid, having an angel of 136.5° between the opposite faces at the vertex, is forced into the surface of a test piece and the length of the diagonals of the indentation left in the surface after removal of the test forced is measured.

AUTOMATIC VICKERS

The Vicker hardness test is an indentation hardness test in which a square-based diamond pyramid, having an angel of 136.5° between the opposite faces at the vertex, is forced into the surface of a test piece and the length of the diagonals of the indentation left in the surface after removal of the test forced is measured.

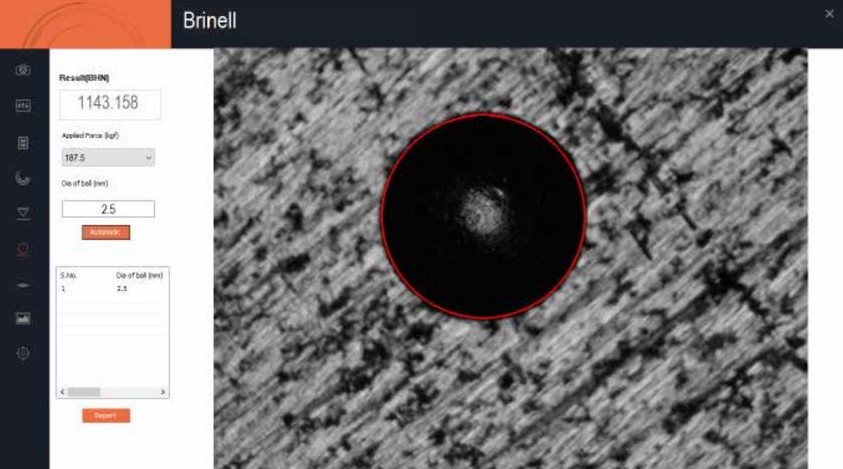

MANUAL BRINELL

The Brinell hardness test is an indentation hardness test in which a hard metal ball is forced into the surface of a test piece and the mean diameter of the indentation left in the surface after removal of the test force, is measured.

AUTOMATIC BRINELL

The Brinell hardness test is an indentation hardness test in which a hard metal ball is forced into the surface of a test piece and the mean diameter of the indentation left in the surface after removal of the test force, is measured.

MANUAL KNOOP

The Knoop hardness test is an indentation hardness test in which a rhombic-based diamond pyramid, having an included longitudinal edge angel of 172.5° and an included transverse edge angle of 130°, is forced into the surface of a test piece and the length of the long diagonal of the indentation left in the surface after removal of the test force is measured.

AUTOMATIC KNOOP

The Knoop hardness test is an indentation hardness test in which a rhombic-based diamond pyramid, having an included longitudinal edge angel of 172.5° and an included transverse edge angle of 130°, is forced into the surface of a test piece and the length of the long diagonal of the indentation left in the surface after removal of the test force is measured.

SETTINGS

The Module SETTING is designed to set various parameters for first time when software is installed. The setting options are available to choose ISO/ASTM standard calibration, setting in report format, setting of various parameter on printed image in report. Once all settings are done, you need one button click for all Analysis. All settings are stored till you change them in future. Do not change them in routine, it is not necessary.

REPORTING DATA

REPORT IS AVAILABLE IN THIS MODULE FOR PREVIEW BEFORE PRINT.

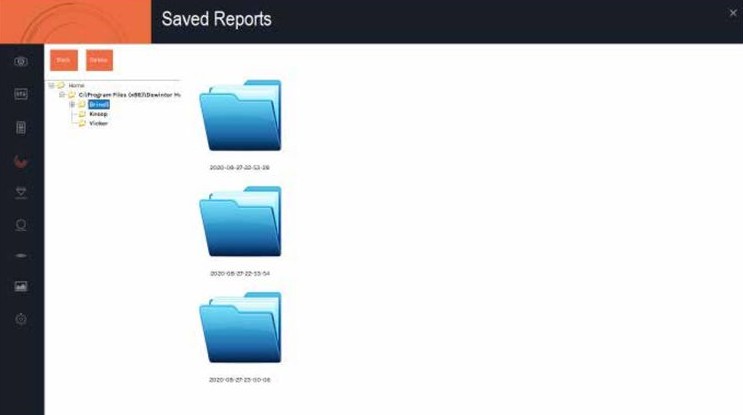

SAVED REPORTS

The Module SETTING is designed to set various parameters for first time when software is installed. The setting options are available to choose ISO/ASTM standard calibration, setting in report format, setting of various parameter on printed image in report. Once all settings are done, you need one button click for all Analysis. All settings are stored till you change them in future. Do not change them in routine, it is not necessary

No technical specifications available for this product.