High-Temperature Resistance: The wedge is specifically designed to withstand temperatures up to 150°C, making it ideal for inspections in high-temperature environments such as furnaces, pressure vessels, and boilers.

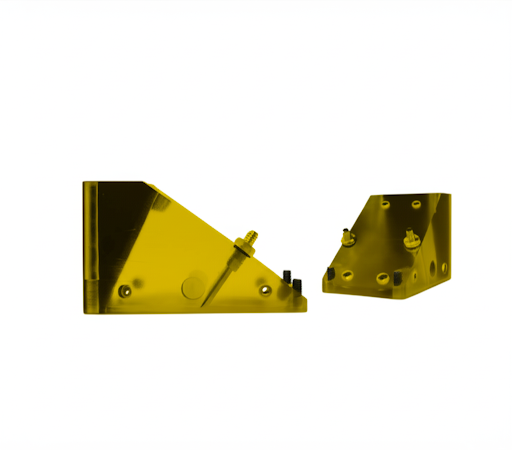

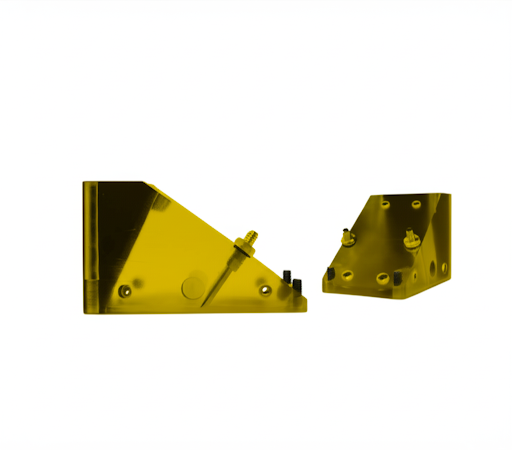

Precision Alignment: Ensures precise alignment of the PAUT (Phased Array Ultrasonic Testing) wedge for accurate ultrasonic inspection results, even in extreme conditions.

Durable Construction: Made from high-quality, heat-resistant materials (such as ceramic or stainless steel) to maintain structural integrity at elevated temperatures.

Stable Positioning: Provides stable and secure positioning of the PAUT wedge during inspection, ensuring accurate and repeatable results every time.

Versatile Compatibility: Designed to accommodate a variety of PAUT wedge sizes and configurations, making it suitable for a wide range of testing applications.

Conducting ultrasonic phased array inspections on components operating at elevated temperatures presents several challenges. Conventional phased array probes utilize piezoelectric elements and internal connections that are highly sensitive to heat and may suffer damage under such conditions. To address this issue, Ucomax has developed an innovative solution capable of performing manual phased array inspections at temperatures reaching up to 150 °C.

Engineered with advanced heat-resistant materials and optimized internal architecture, Ucomax’s high-temperature phased array technology ensures consistent performance and signal integrity even under demanding thermal environments. This advancement enables industries to conduct reliable inspections without extensive cooling periods, thereby reducing operational downtime and supporting the continued safe operation of critical assets.

No technical specifications available for this product.