At UCOMAX, Research & Development is more than a service — it’s the core of our promise to deliver customized, high-precision solutions for industries where reliability and performance can’t be left to chance.

We partner with clients to transform ideas into proven, production-ready systems that solve real operational challenges, extend equipment life, and unlock new efficiencies.

From new product development and advanced reverse engineering to embedded electronics and smart system integration — our R&D division turns complex challenges into practical, measurable results. what sets us apart:

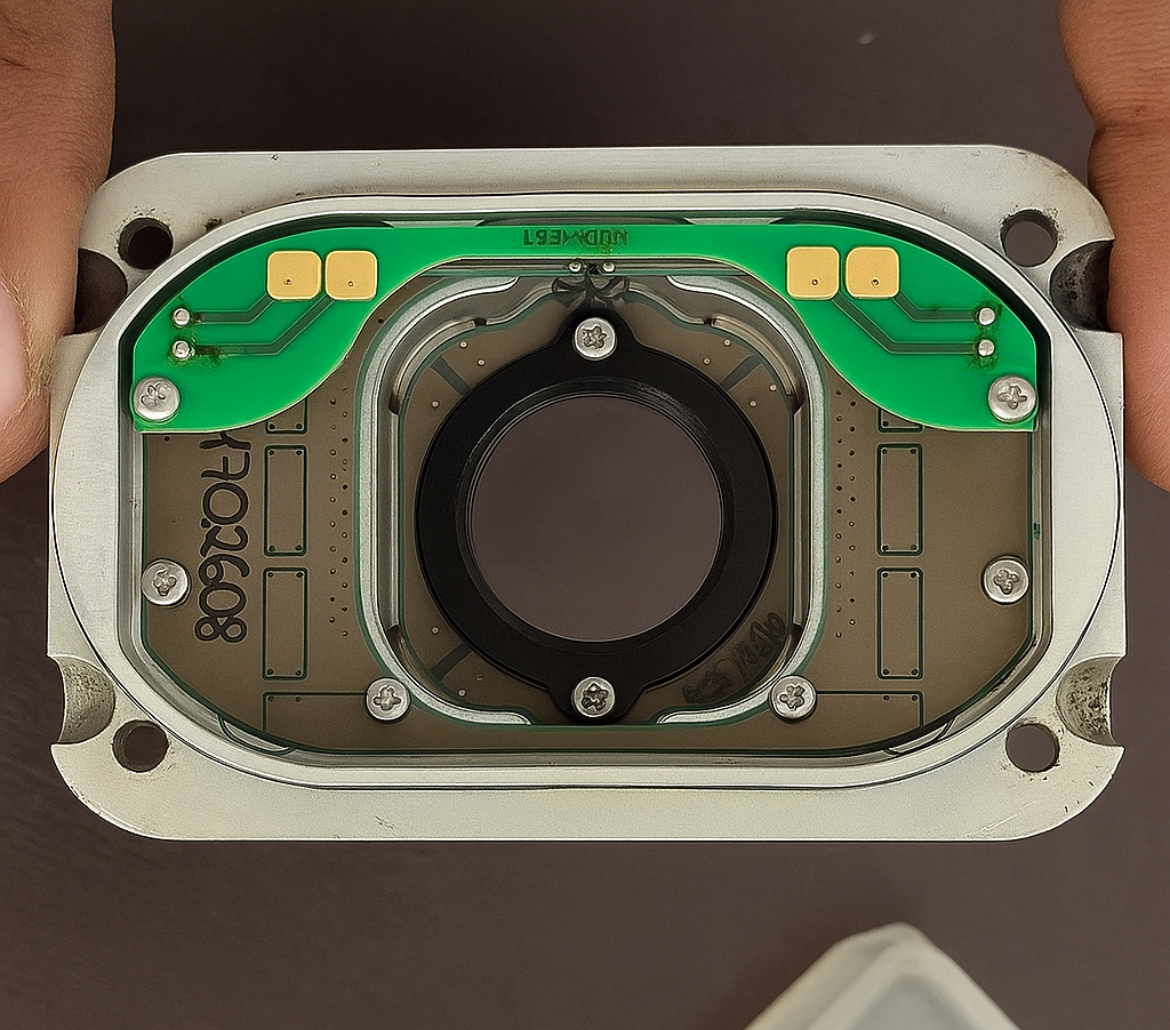

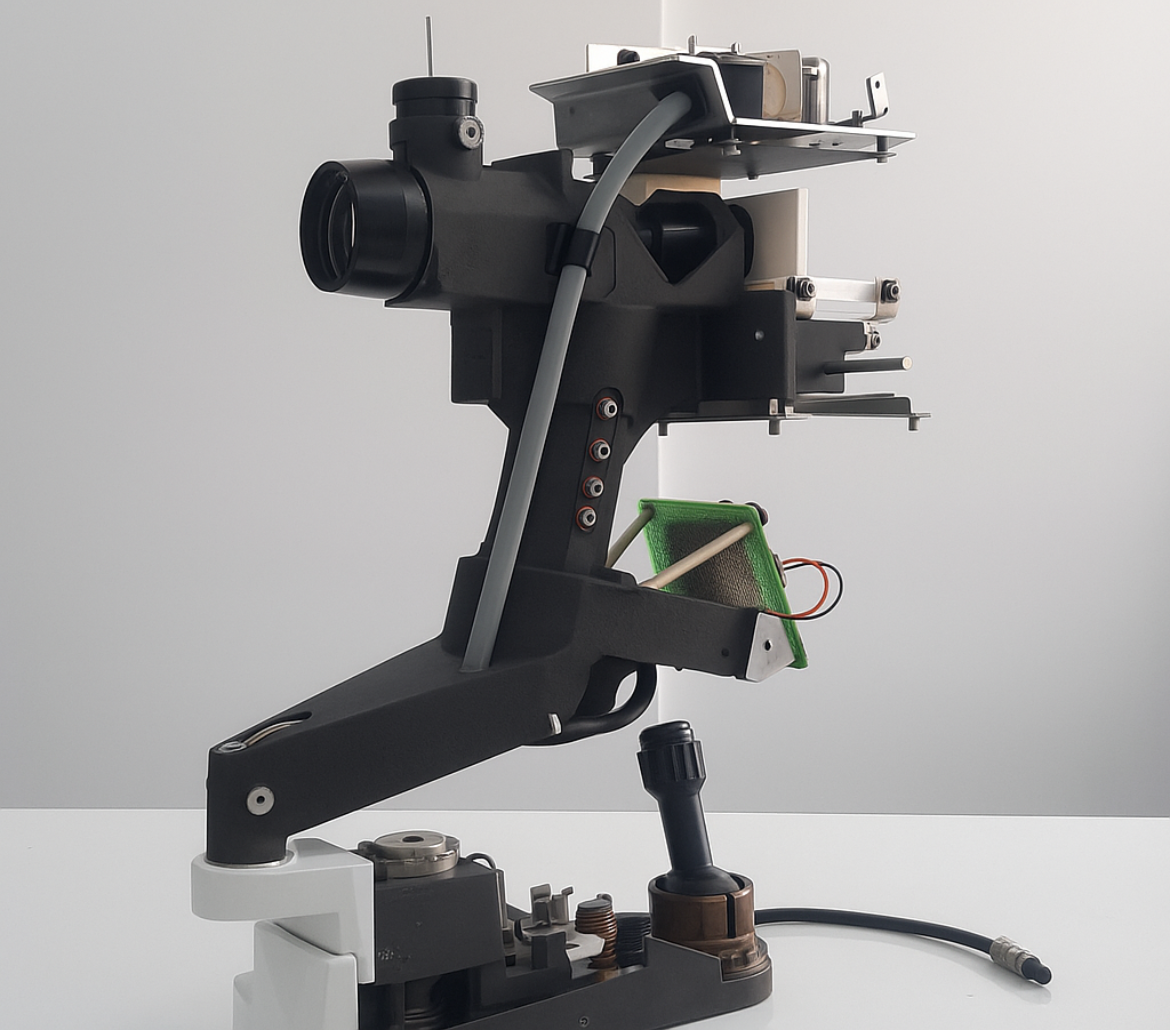

Legacy parts are a common bottleneck in critical industries. UCOMAX goes beyond simple 3D scanning — we study the entire part’s interaction with its system, understand why it was built the way it was, and redesign where needed to deliver equal or superior performance.

Where original manufacturers no longer exist, our clients gain full control of replacement parts — with updated documentation, local production support, and freedom from obsolete supply chains.

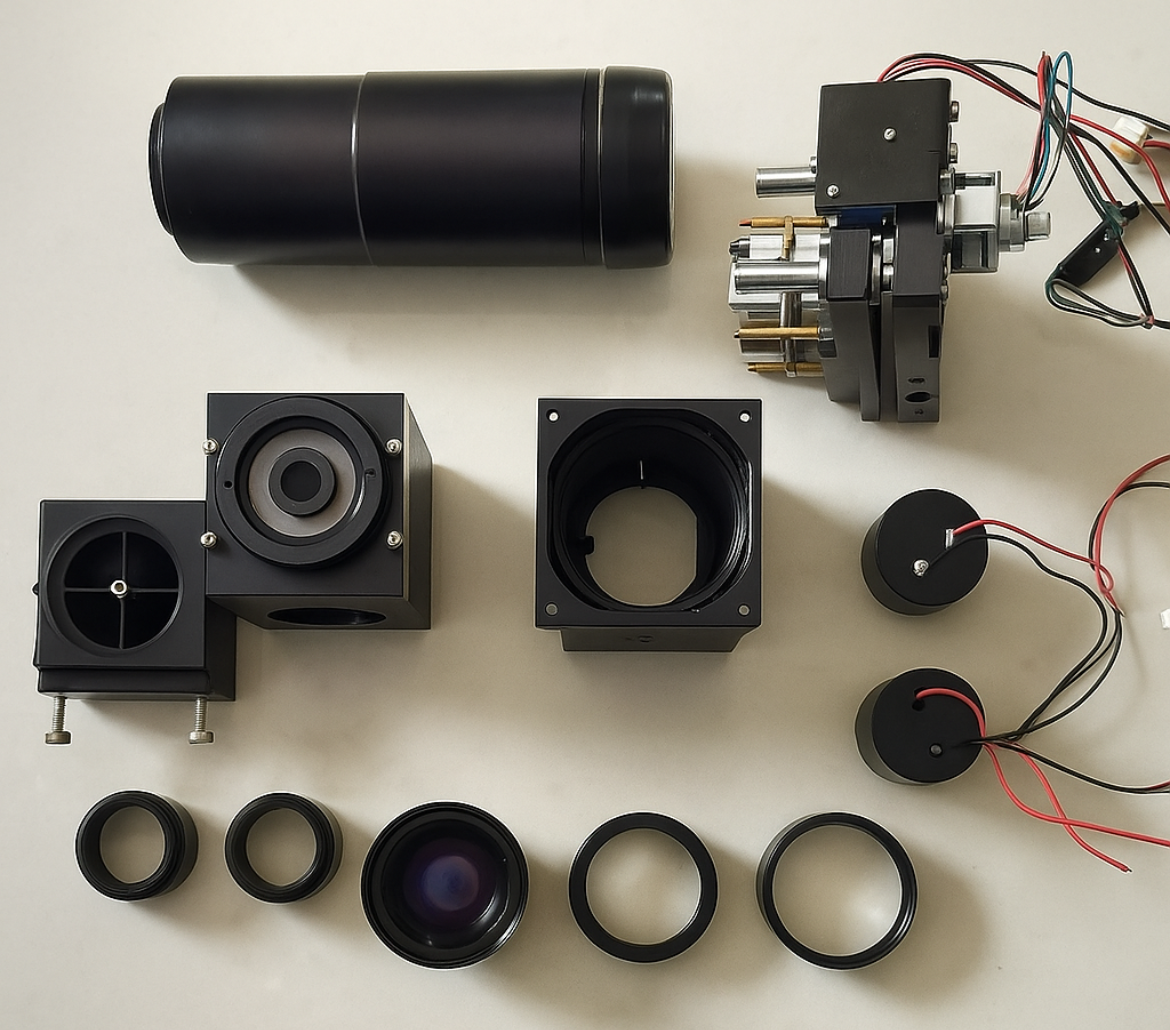

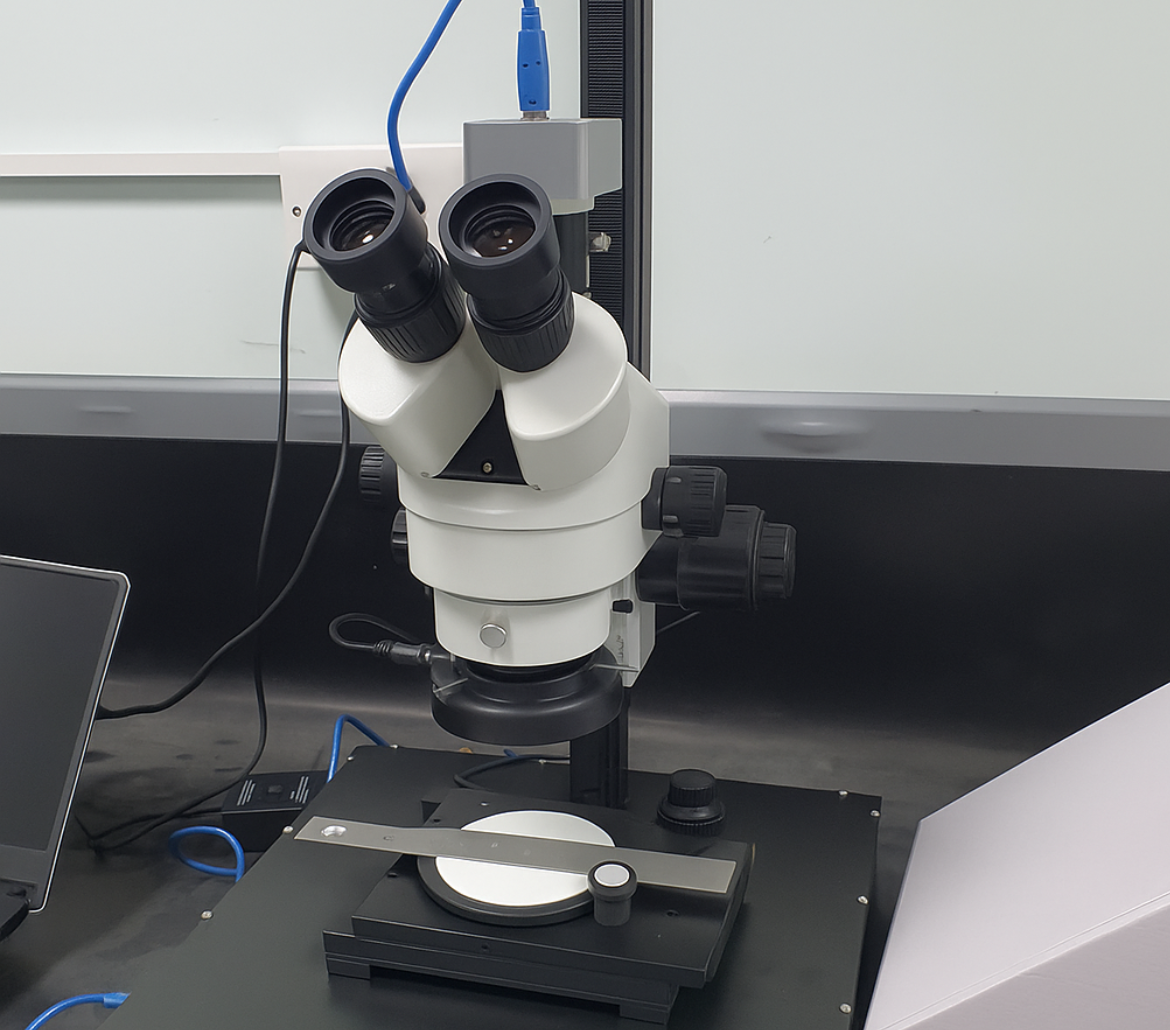

At UCOMAX, every critical stage of research, design, prototyping, and testing is managed entirely in-house. By combining our design studio, advanced scanning and inspection lab, electronics workshop, and prototype manufacturing unit under one roof, we maintain complete control over quality, timelines, and confidentiality. This integrated setup allows our engineers to iterate faster, resolve design challenges on the spot, and deliver functional, validated solutions without relying on fragmented vendor chains — ensuring you get a precise, ready-to-implement outcome, every time.

We believe true engineering innovation balances performance with real-world practicality. UCOMAX designs are developed not just for technical excellence but for ease of production, straightforward maintenance, and cost efficiency over the entire lifecycle. By selecting the right materials, simplifying complex geometries, integrating readily available components, and optimizing for local manufacturing, we help clients reduce total project costs without compromising reliability — delivering custom solutions that are robust, sustainable, and commercially viable.

We understand that R&D means trust. Every project at UCOMAX is governed by strict confidentiality, secure data handling, and clear IP agreements.

Your design data, test results, and final documentation are fully protected — so you can take your new solution forward with complete ownership and peace of mind.

Whether you are an OEM, a maintenance contractor, or an asset owner, working with UCOMAX means having a flexible, transparent, and technically strong partner that adapts to your internal processes and priorities.

Our clients value the fact that they can trust us with critical, sensitive, or complex projects — without the cost and risks of setting up and maintaining extensive in-house R&D resources.

Our R&D process is structured yet flexible, allowing us to handle both well-defined scopes and open-ended exploratory projects. Typical stages include:

No technical specifications available for this product.