Magnetic Flux Leakage (MFL) Technology: MFL Tubes utilize Magnetic Flux Leakage technology to detect surface and subsurface defects, such as corrosion and cracking, in ferrous materials with high precision.

High Sensitivity: Offers superior sensitivity for detecting even the smallest defects, ensuring thorough inspection of pipes, tubes, and other cylindrical structures.

Non-Destructive Testing (NDT): The MFL Tubes perform non-destructive testing, ensuring no damage to the material while detecting critical defects, making it ideal for inspections without compromising the integrity of the components.

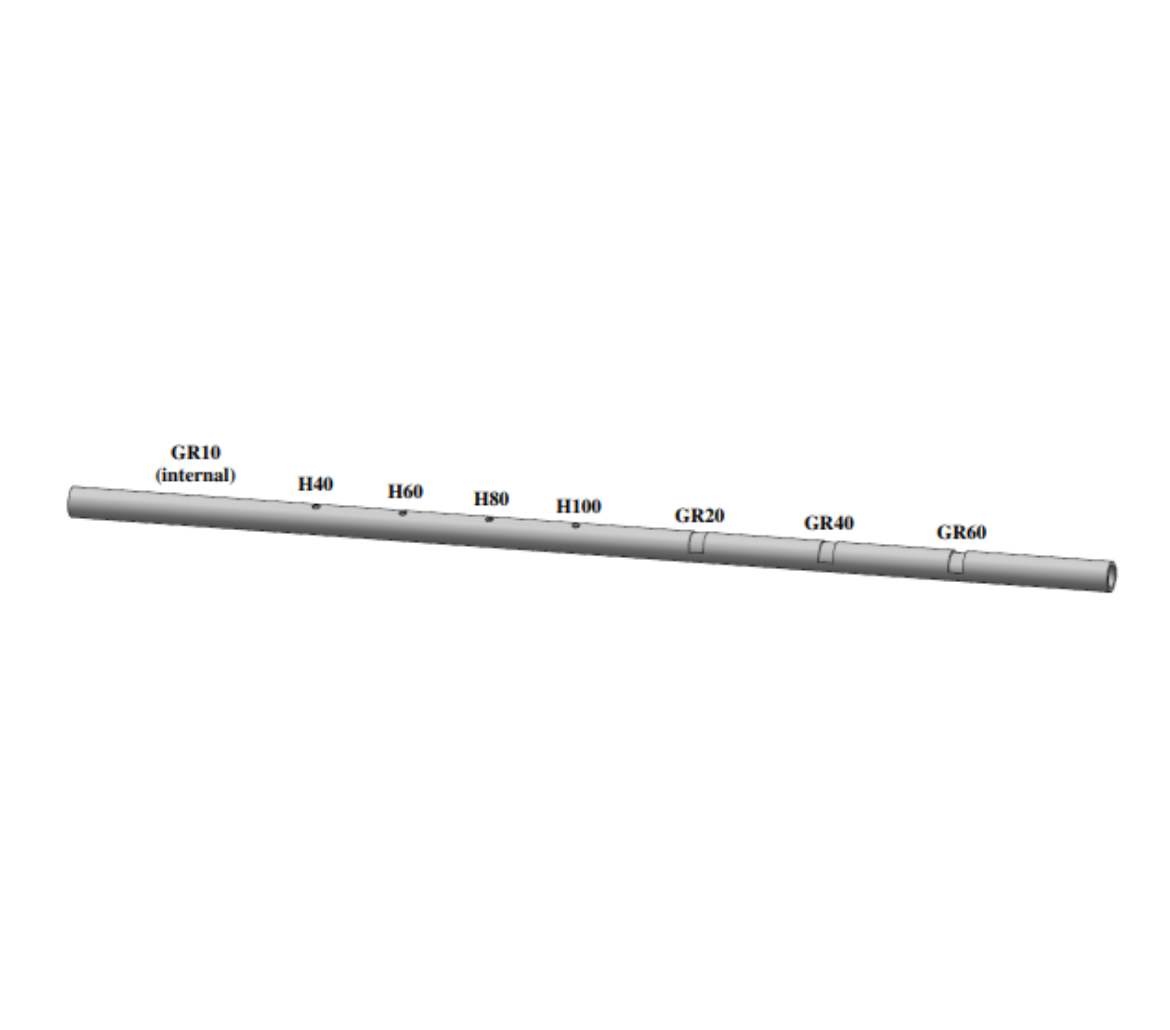

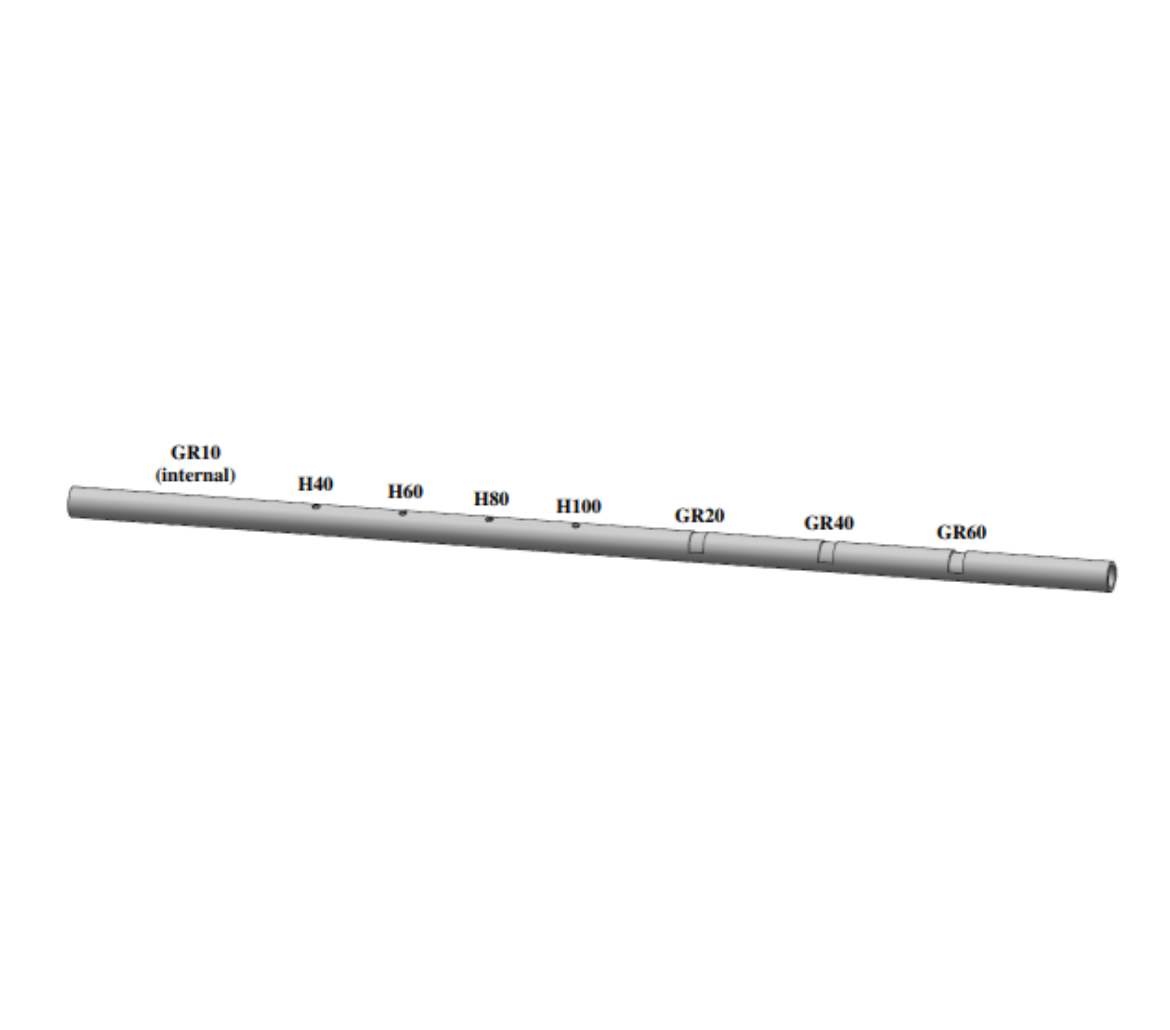

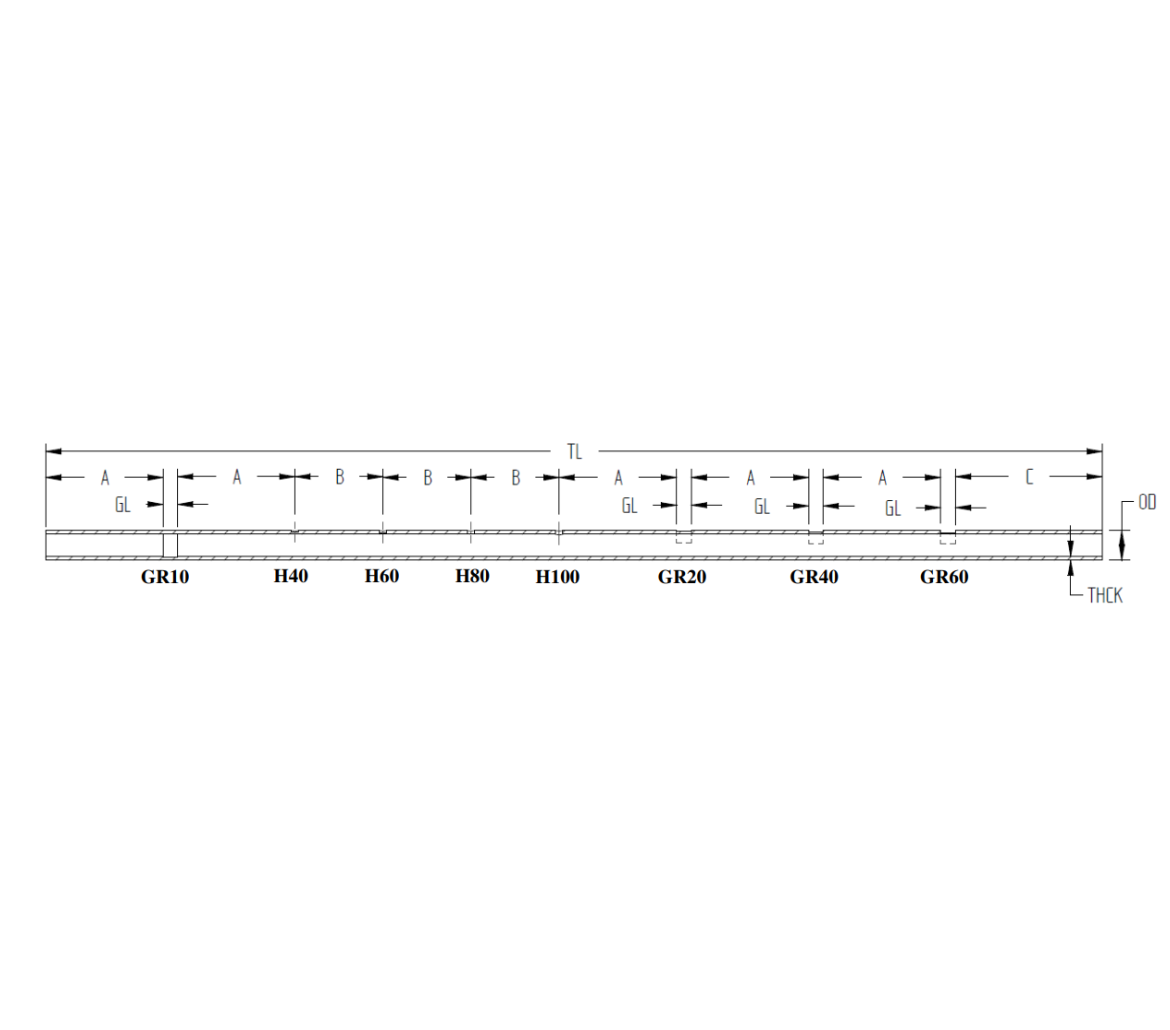

MFL Tubes (Magnetic Flux Leakage Tubes) are designed to offer high-precision detection of surface and subsurface defects in ferrous materials using Magnetic Flux Leakage (MFL) technology. This technology allows for the detection of defects such as corrosion, cracking, pitting, and other types of damage without causing any harm to the material being tested, making it an essential tool in non-destructive testing (NDT).

MFL Tubes are typically used for inspecting pipelines, tubes, storage tanks, and other critical components in industries like oil and gas, power generation, and chemical processing. These tubes are known for their ability to detect even the smallest defects, which helps reduce the risk of catastrophic failures and ensure the safety of industrial systems.

No technical specifications available for this product.