High Sensitivity Detection: NFT Tubes use Near Field Eddy Current Technology to detect very small surface and subsurface defects, offering superior sensitivity for flaw detection in a wide range of materials.

Advanced Inspection Capabilities: Capable of detecting corrosion, cracking, material thinning, and other surface imperfections, NFT Tubes provide precise, non-destructive inspection capabilities for tubular components.

Non-Destructive Testing (NDT): These tubes use NDT methods, allowing for detailed analysis without damaging the integrity of the material being tested, ideal for high-precision applications in industries like power generation, nuclear, and chemical processing.

NFT Tubes or Near Field Eddy Current Tubes, are designed for high-precision non-destructive testing (NDT) applications. By using Near Field Eddy Current Technology, these tubes offer exceptional sensitivity for detecting small defects and imperfections in ferrous and non-ferrous materials. NFT Tubes are particularly useful for industries where accurate and reliable tube inspections are critical to avoid downtime and ensure the safety of equipment.

These tubes are typically used in heat exchangers, boilers, and other critical systems where early detection of material degradation can prevent costly repairs and catastrophic failures. Their advanced detection capabilities allow for real-time monitoring, giving engineers and operators the ability to take immediate corrective action if defects are identified.

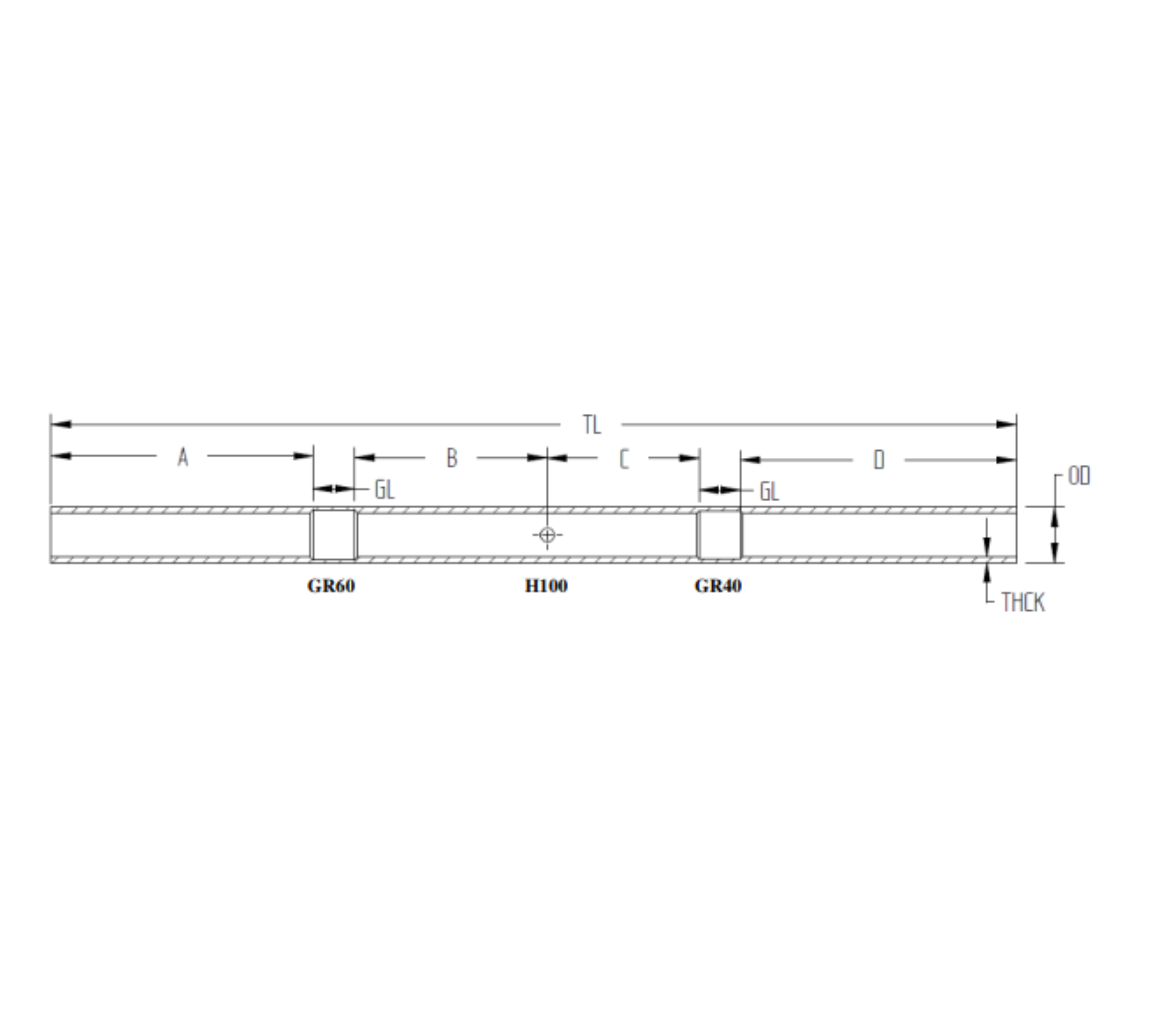

No technical specifications available for this product.