Advanced Image Analysis for Welding Inspections: Designed for inspectors, metallurgists, and material scientists.

Supports Multiple Image Formats: Compatible with BMP, JPEG, TIFF, PNG, GIF, and PSD.

Real-Time Live Image Capture: Capture and analyze live images on the same platform.

Comprehensive Annotation Tools: Includes lines, shapes, text, arrows, grids, and more for easy documentation.

Customizable Measurement Settings: Set parameters for depth, penetration, leg length, throat length, and more.

Automatic Edge Detection: Detect and measure weld parameters with precision.

Weld Defect Detection: Identify defects like cracking and porosity in welds to ensure quality.

INTRODUCTION OF WELD SCAN

WELD SCAN is a new generation image analysis software, meant for welding inspectors, metallurgist and material scientist for analyzing weld dimensions. It is a single Window based systemINTRODUCTION OF WELD SCAN WELD SCAN is a new generation image analysis software, meant for welding inspectors, metallurgist and material scientist for analyzing weld dimensions. It is a single Window based system

Some components involve large numbers of welding joints. WELD SCAN tool is used to record all the necessary testing procedures in measurement profiles represented in different colors.

The WELD SCAN software can handle both grey monochrome (8bit) and color (24bit) image. Multiple images of any size can be opened and displayed on the screen for analysis or comparison. The software supports the most common formats like BMP, JPEG, TIFF, PNG, GIF, and PSD. Live images also can be observed and captured on the same platform. Since the system is in a Window environment, graphs and charts displayed on the monitor can be quickly transferred into other Windows based programs such as, MS Word, MS Excel or any other commercial Windows based software for the purpose producing reports and presentations.

ANNOTATION

Annotation features allows quick and easy Documentation of your image tools. The available tools are: line between two points, horizontal line, vertical line, freehand line, two parallel lines, perpendicular lines, Square, Circle, Text, Arrow, Grid, Cross lines from center, scale bar, highlighter. The text color & Thickness of line can be designated.

CAPTURE CAMERA

One can select different display/capture sizes along with other setting like white balance, brightness, contrast, Hue, Saturation can be changed on live displayed image. Once all setting are done, image can be captured in appropriate folder for appropriate analysis.

CALIBRATION

Calibration should be performed on all the objectives of the microscope, where Digital Camera is installed. Calibration should be performed only when all hardwares are finally fixed. In case of readjustments or replacement of any part, calibration should be done again.

FILLET MEASUREMENT

All dimensional measurements.

• Programmable (Automatic) measurement

• Supports all weld quality parameters like depth/penetration, %penetration, leg lengths, throat lengths, root penetration etc.

• Can define Component and its parameters to be measured

• Can measure length, area, angle, diameter, radius, circumference in addition to weld penetration measurement

• Can set expected values and tolerances for each parameter

• Automatic edge detection

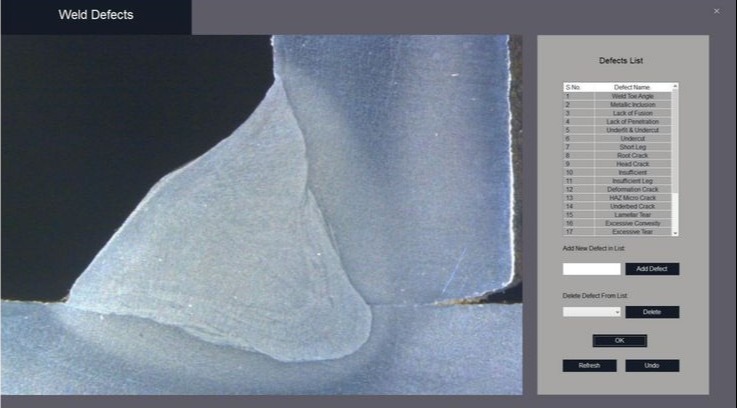

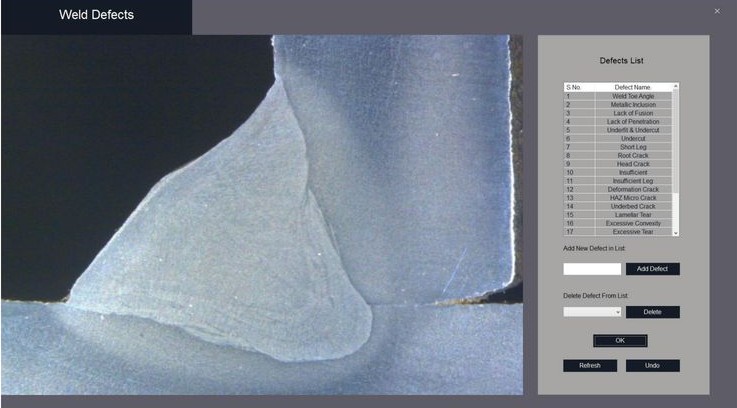

WELD DEFECTS

Weld defects such as cracking and porosity have a great effect on the performance of the weld bead. Samples taken after the LSM process, with different manufacturing parameters, were checked to verify the occurrence of porosity and cracking. shows a typical solidification crack and porosity in the weld bead. show the relationship between LSM parameters and porosity and cracking defects, respectively.

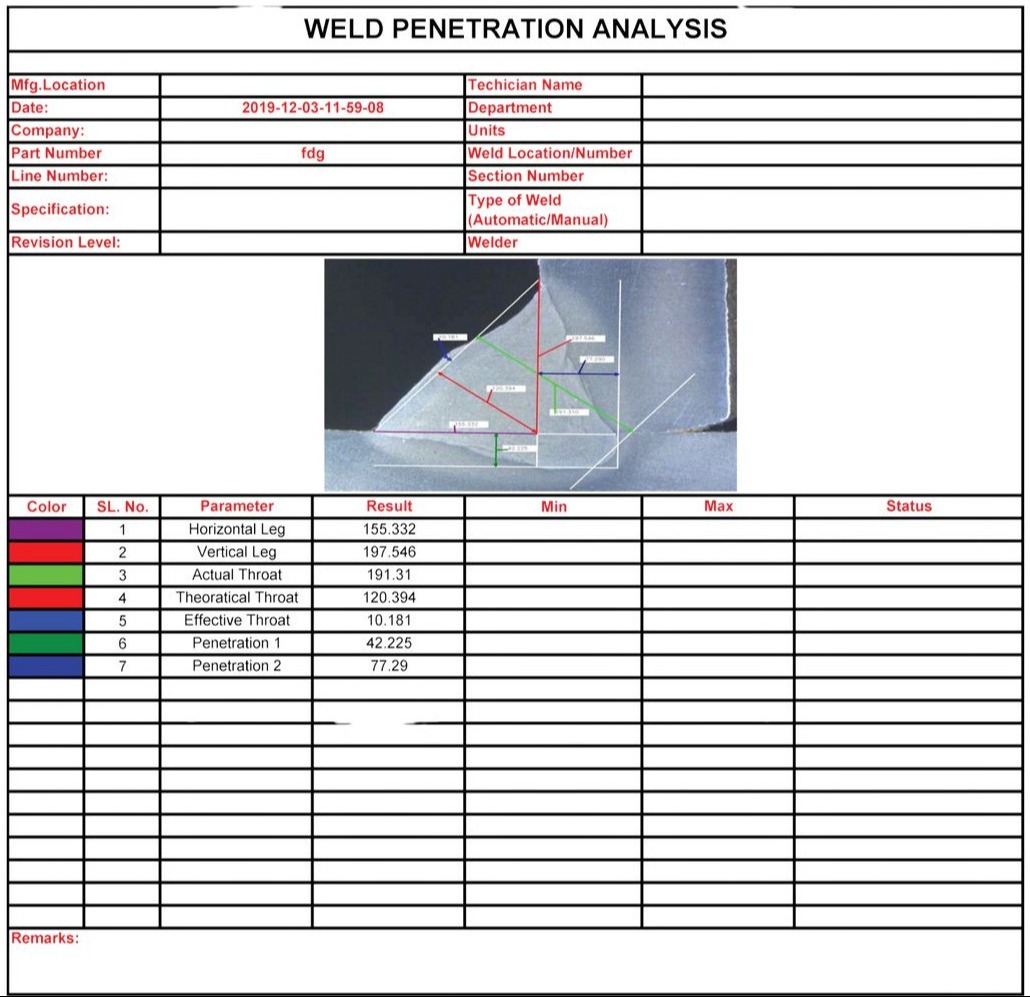

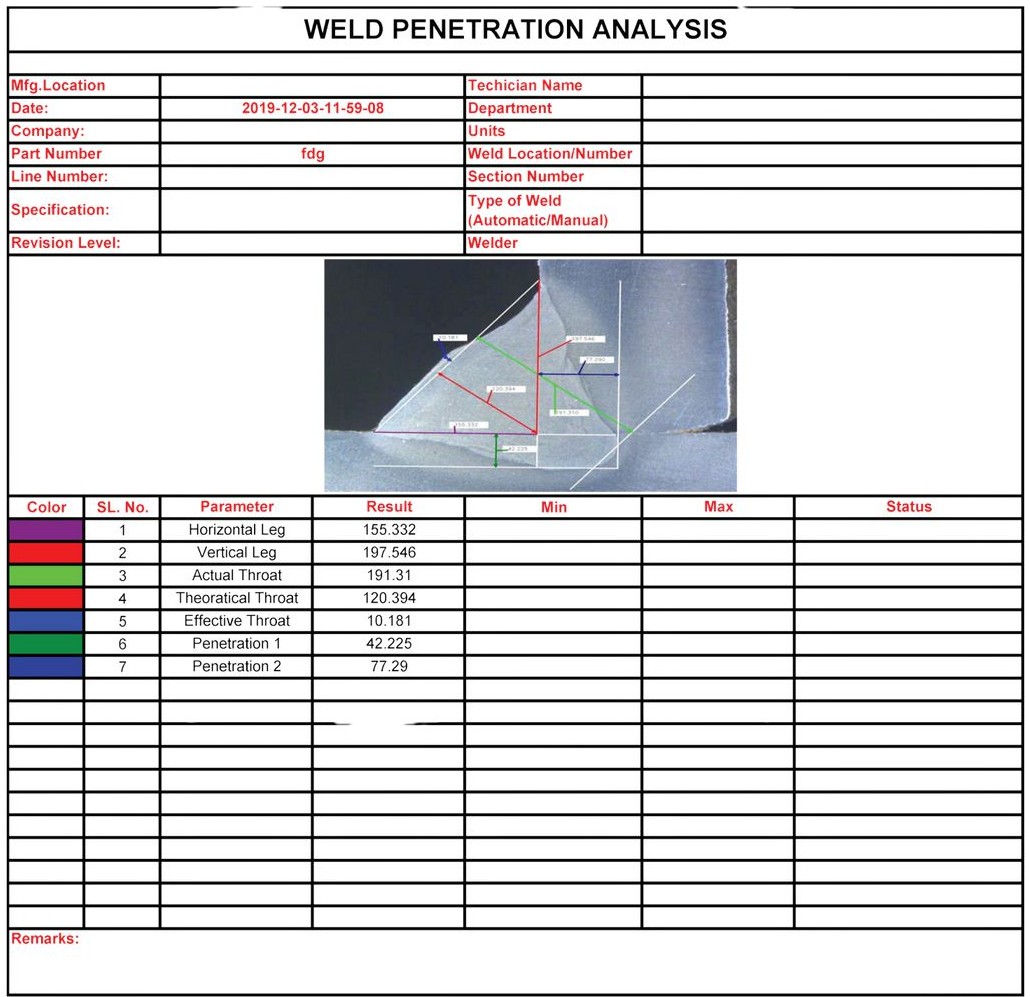

WELD PENETRATION REPORT

| Modules Included | |

| Camera capture | Capture live images with adjustable display size, brightness, contrast, hue, saturation, and white balance. Images are saved in dedicated folders. |

| Calibration | Calibration is performed per microscope objective. Must be redone after any hardware adjustments or replacements. |

| Annotation | Annotate images using tools like lines, shapes, arrows, grids, crosshairs, text labels, and highlighters. Customizable colors and line thickness. |

| Fillet measurement | Supports automated and manual measurements of weld profiles including depth, leg lengths, throat size, angles, radius, and more. |

| Defect detection | Detects and documents weld defects like porosity and cracking. Enables correlation with process parameters for LSM and post-weld evaluations. |

| Reporting | Detailed weld penetration reports can be generated for each sample, including measurement overlays and defect documentation. |