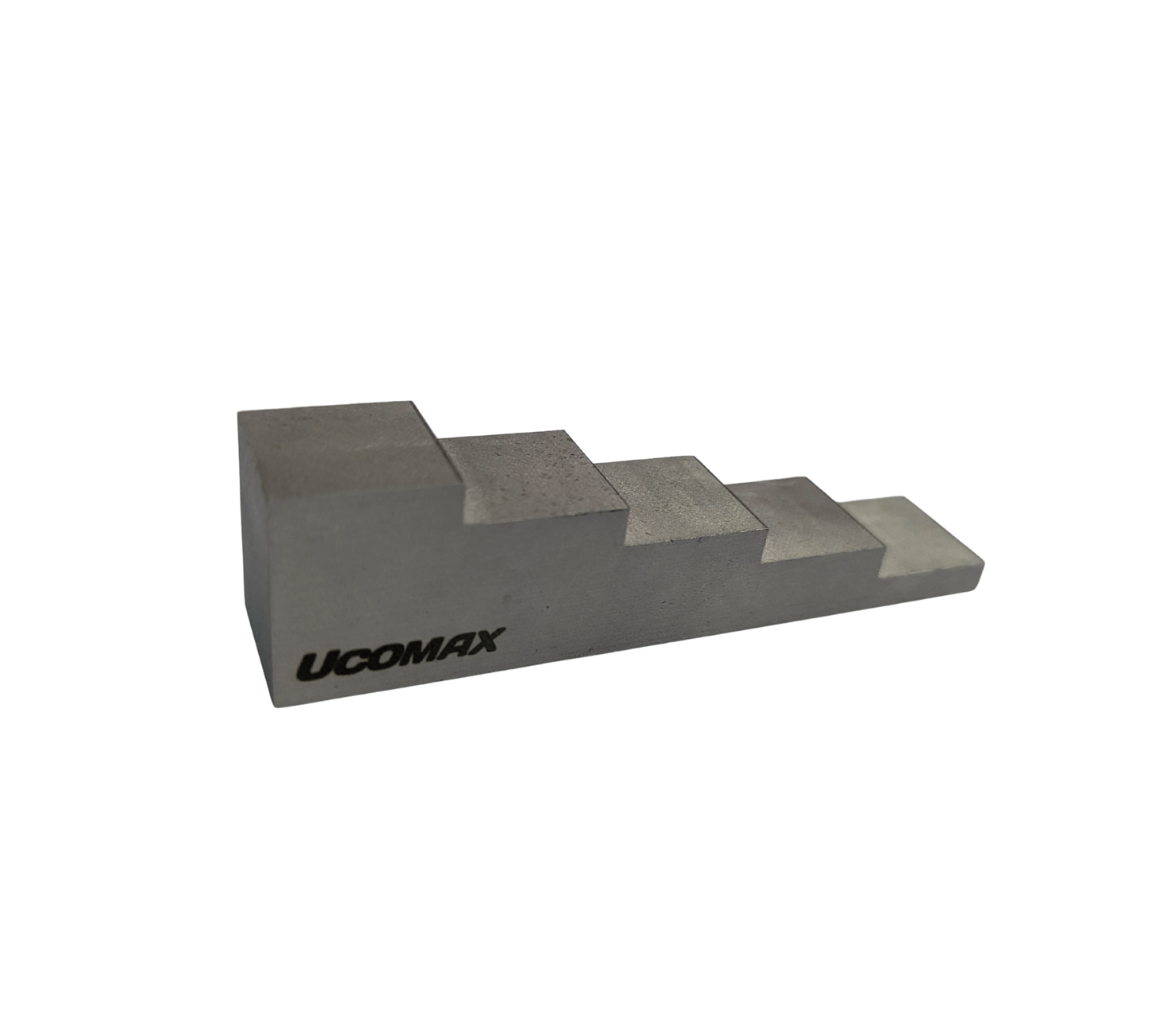

UCOMAX manufactures high-precision Step Blocks used for the calibration and verification of thickness measuring instruments, primarily in ultrasonic testing (UT) and other Non-Destructive Testing (NDT) applications. Each block is precisely machined with a series of flat steps of known thicknesses. These steps help inspectors check instrument accuracy, verify linearity, and ensure reliable measurements across a range of wall thicknesses and materials.

No technical specifications available for this product.