Advanced Inspection Technology: IRIS Tubes use the Internal Rotating Inspection System (IRIS), which is a highly effective ultrasonic inspection technique for detecting corrosion, pitting, and other internal defects within pipes, tubes, and other cylindrical structures.

High Sensitivity: Capable of detecting even the smallest surface and subsurface defects, offering a high-resolution inspection of internal structures with unmatched precision.

Non-Destructive Testing (NDT): Provides non-destructive testing, meaning it doesn’t damage the material being inspected while identifying flaws, which makes it ideal for critical infrastructure inspections.

IRIS Tubes utilize ultrasonic waves to inspect the internal surfaces of pipes and tubes. By emitting sound waves and measuring the time it takes for them to reflect back from the inner surface of the tube, IRIS technology provides a clear and precise picture of the inner integrity of the material. This makes it highly effective in detecting corrosion, pitting, and other types of structural damage.

IRIS Tubes are used across a range of industries for preventive maintenance, quality control, and asset integrity monitoring. The technology allows for comprehensive wall thickness measurement, helping engineers and technicians understand the degree of material degradation over time, thus enabling better decision-making regarding repair or replacement.

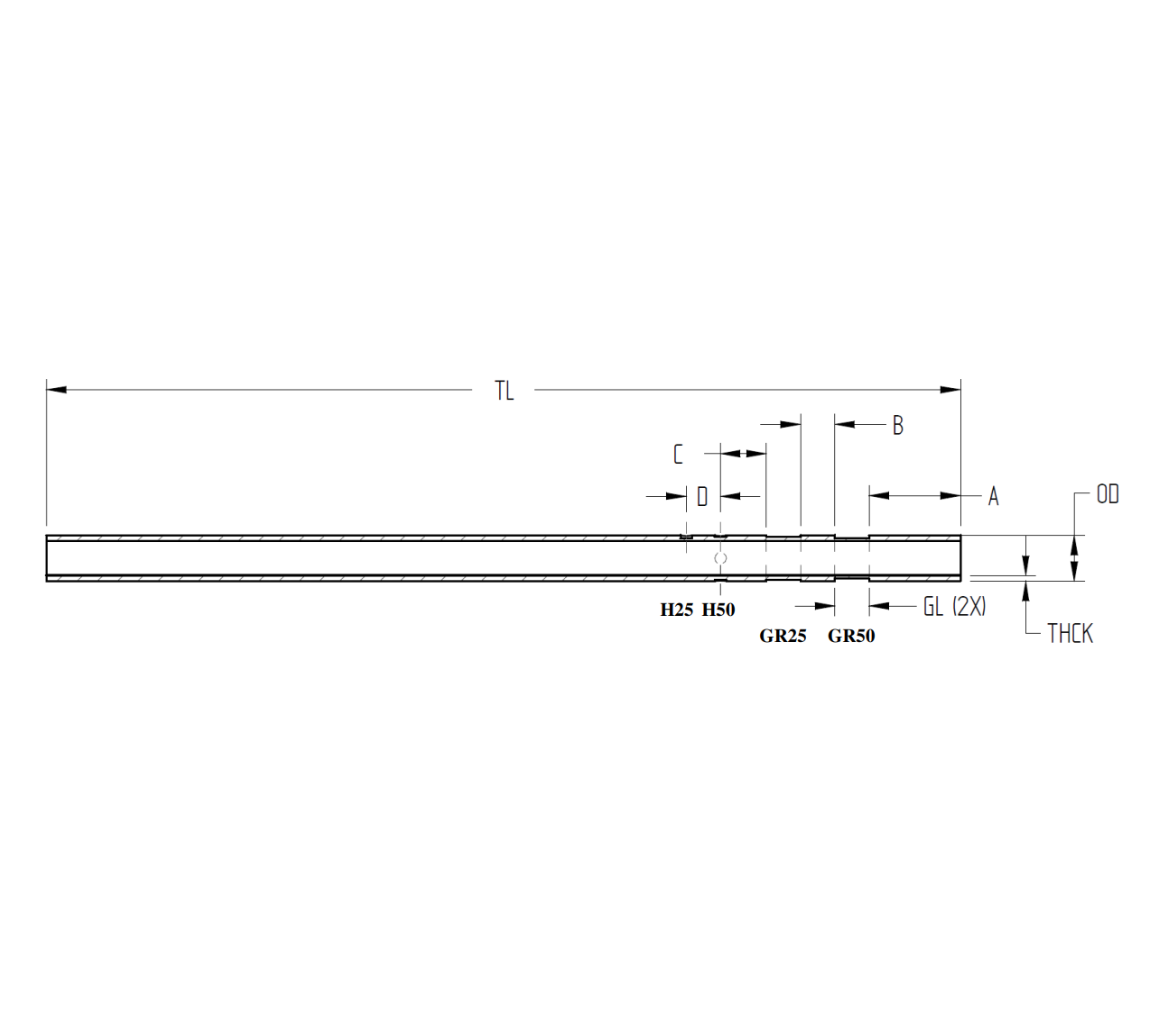

No technical specifications available for this product.