Powerful Microstructural Analysis: Measure and quantify critical features such as grain size, impurities, second phases, porosity, SDAS, and defects — all within one workflow.

Live Camera Control: Adjust and capture high-quality images in real-time. Fine-tune settings like white balance, brightness, contrast, hue, and saturation for optimal imaging.

Accurate Calibration: Calibrate your microscope objectives and camera once your hardware is set. Maintain measurement precision with easy recalibration when needed.

Flexible Measurement Tools: Obtain precise measurements using manual lines, shapes, or outlines — log and export results seamlessly to spreadsheets for further analysis.

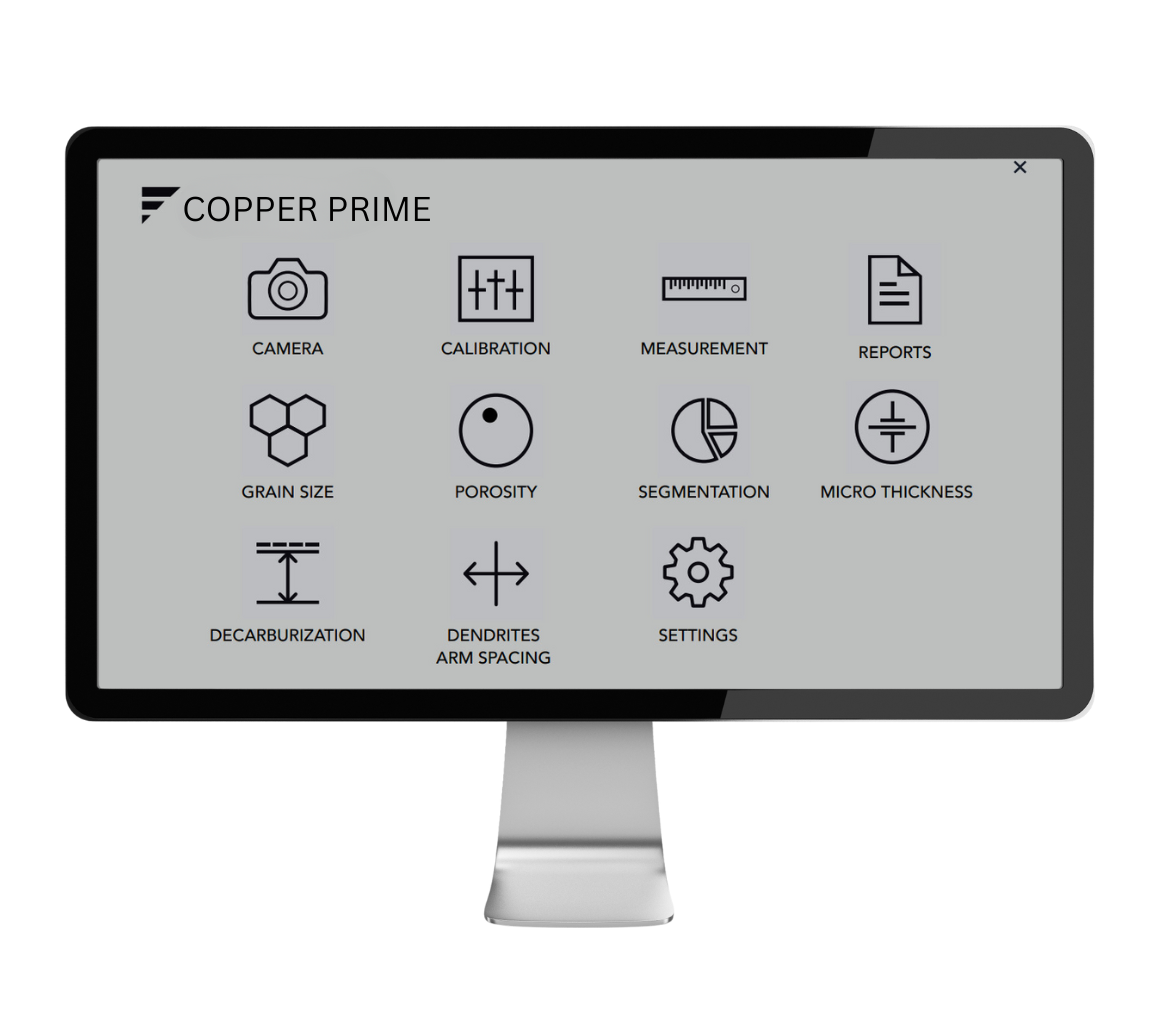

Copper Prime is a specialized microstructure analysis software built for copper and its alloys. It supports quality control, failure analysis, and research by allowing precise evaluation of key metallurgical features such as grain size, porosity, second phase content, dendrite arm spacing (DAS), impurities, and structural defects.

The software enables users to quantify these characteristics and compare them to acceptance criteria, following standardized methods. With modular tools like segmentation, measurement, and coating thickness analysis, Copper Prime provides a flexible and reliable solution for copper-based metallography.

Key Highlights:

| Modules Included | |

| Camera | Capture images with adjustable settings like brightness, contrast, hue, saturation, and white balance. Images are saved in folders for later analysis. |

| Calibration | Performed on all microscope objectives after installation. Required again only if hardware is adjusted or replaced. |

| Measurement | Manual measurements using drawn lines or shapes. Data can be stored, printed, or exported for further analysis. |

| Grain size | Fully automated and interactive analysis based on ASTM E112. Detects twinned, equiaxed grains typical of annealed copper structures. |

| Dendrite arm spacing (DAS) | Evaluates primary and secondary dendrite arm spacing to help assess melt quality and predict casting characteristics. |

| Segmentation | Uses grayscale intensity for phase differentiation. Histogram view with up to 10 threshold settings. Colored overlays display multiple phases simultaneously. |

| Porosity | Identifies pores using filtering and threshold techniques. Useful for mechanical property analysis in powder metallurgy applications. |

| Micro thickness | Measures local coating or plating thickness using cross-sectional optical microscopy. Accuracy up to 0.8 mm under good conditions. |

| Decarburization | Measures decarburization depth based on structural changes in the ferrite layer, following ASTM E-1077-91. |

| Settings | Initial configuration for calibration method, report format, scale bar, and working mode (live or stored images). Settings are stored for future use. |

| Gallery | Organized folders for Measurement, Segmentation, Grain size, Porosity, and Decarburization. Facilitates image access and categorization. |

| Report saving | Automatically saves reports, which can be retrieved anytime from the system. |