Foundry Prime is a comprehensive cast iron microstructure analysis software designed specifically for the foundry and cast iron industries. Built on a touchscreen-friendly platform, it enables precise analysis of nodules, graphite flakes, carbides, and microstructural phases according to ASTM, ISO, and JIS standards. Whether you’re analyzing ductile iron, grey iron, or carbide banding, Foundry Prime streamlines the entire process — from live image capture to automated measurement, classification, and professional reporting — all with single-click simplicity.

Key Hightlights:

Standard Compliant: Analyzes nodules and graphite flakes as per ASTM A247-67 and ISO 945-1 standards. Excludes nodules touching boundaries and artifacts below 10 microns for accuracy.

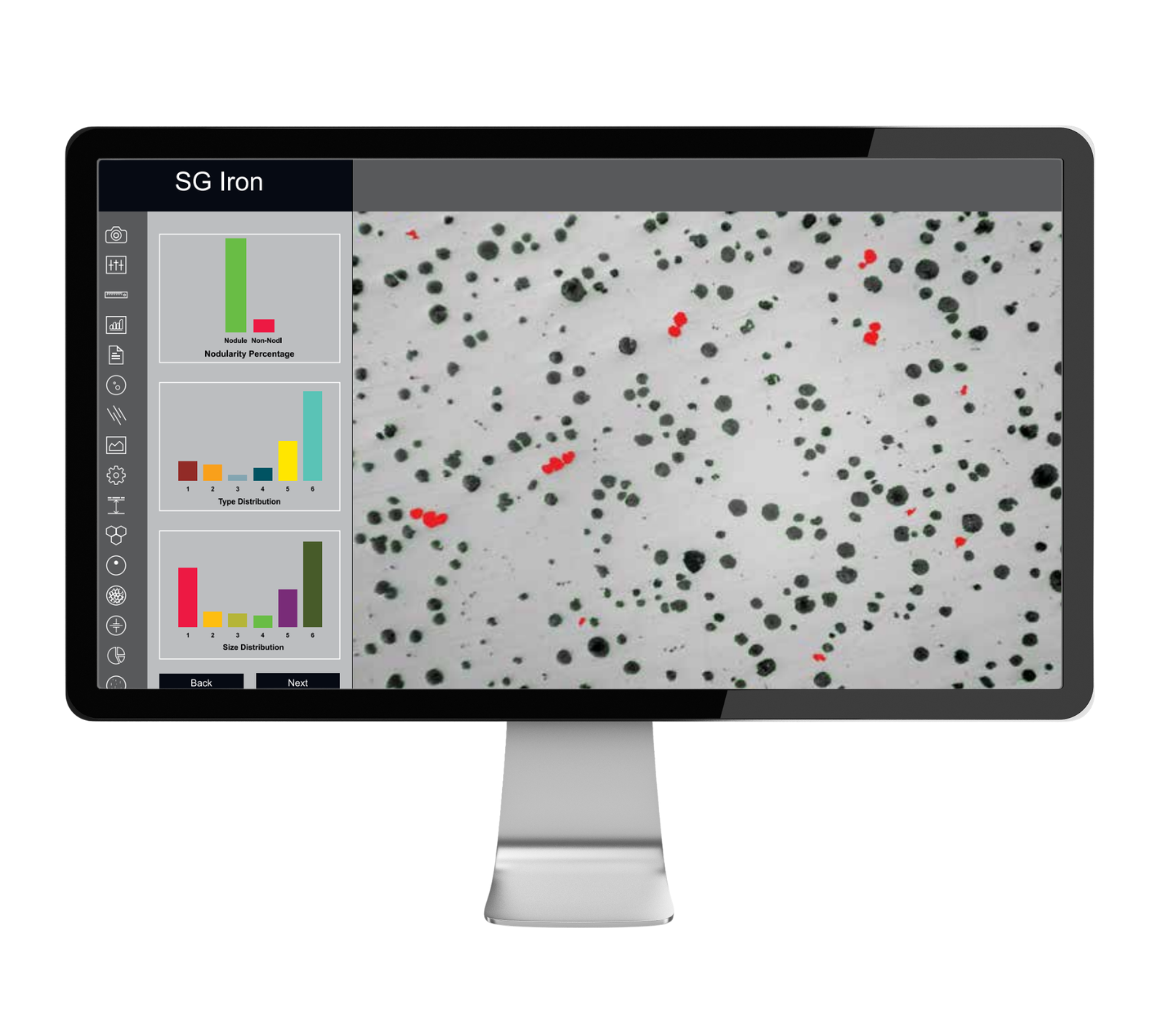

Smart Nodularity & Flake Analysis: Automatically separates nodules from non-nodules based on spheroidicity, size, and form. Reports graphite flake type, size, orientation, and distribution.

Flexible Matrix Analysis: Reports the matrix composition — pearlite, ferrite, graphite, and carbide — for etched samples. Calculates pearlite percentage by excluding graphite area.

One-Touch Automation: Powerful algorithms for segmentation, boundary detection, and neural network classification deliver quick, repeatable results at the push of a button.

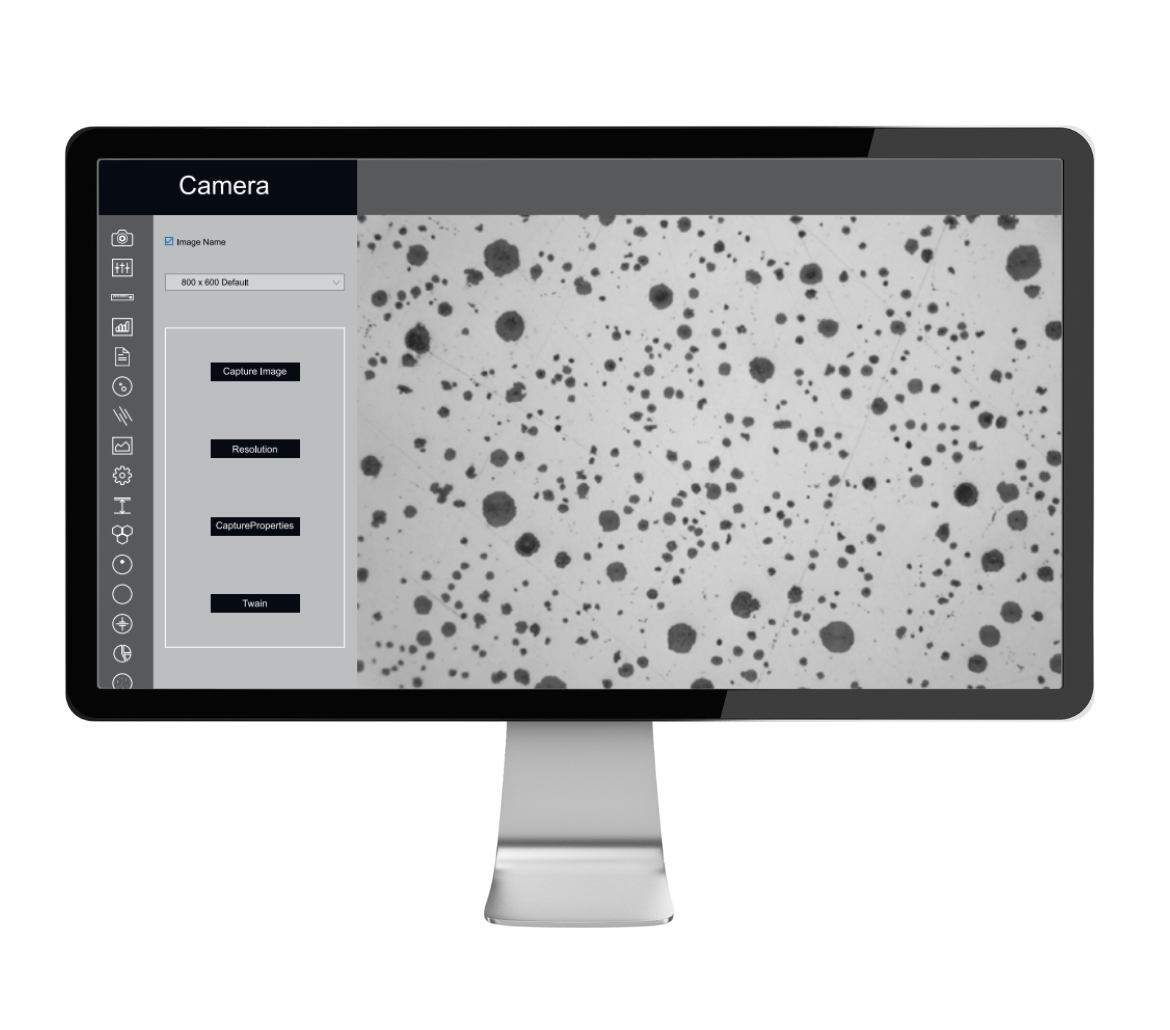

Live Camera Control: Adjust image capture settings in real time — white balance, brightness, contrast, hue, and saturation — to ensure high-quality images every time.

Precise Measurement: Take manual measurements on lines, traces, or shapes. Log results automatically for further analysis, printing, or export to spreadsheets.

Ready Reports: Generate fully formatted reports with your chosen international standards and templates (with or without chemical & physical properties).

Easy Gallery Access: Organize captured images in clear folders for Nodularity, Flake, Carbide, and Line Measurement — retrieve them anytime.

| Module Included | |

| Camera | Select live display or capture sizes. Adjust white balance, brightness, contrast, hue, and saturation. Save images in organized folders for detailed microstructural analysis. |

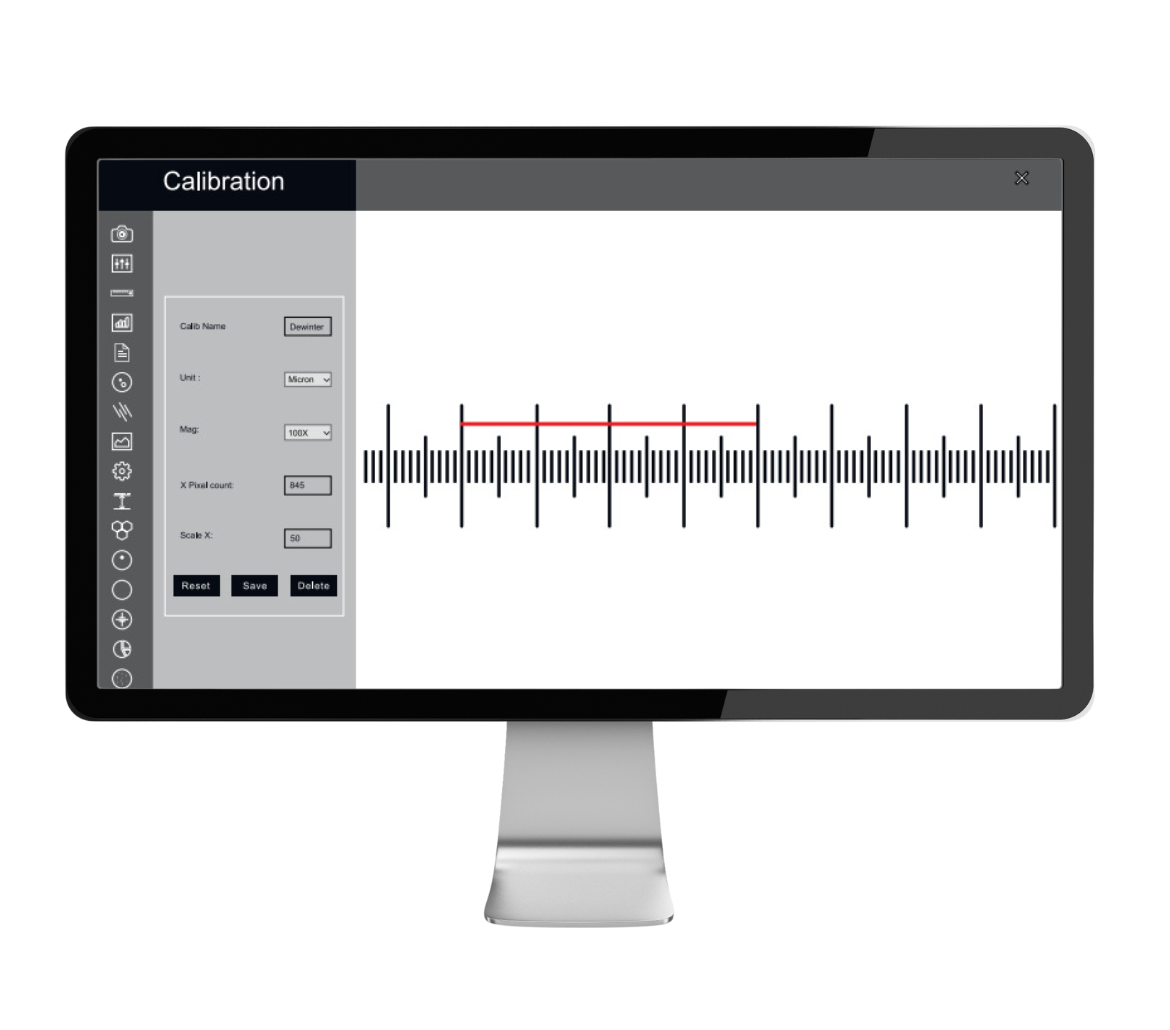

| Calibration | Calibrate all microscope objectives with the installed camera for accurate results. Recalibrate easily when hardware changes occur. |

| Measurement | Manually measure nodules, flakes, lines, and shapes. Log data automatically and export to spreadsheets for advanced statistics and reports. |

| SG Iron (Nodularity) | Analyze ductile iron/nodules (SG Iron) for nodules count, size (1–8), form (I–VI). Excludes nodules touching boundaries and artifacts <10 microns. Complies with ASTM A247-67, ISO 945-1. |

| Gray Iron (Graphite Flakes) | Analyze graphite flake length, type (A–E), size (1–8), orientation, and distribution in grey iron microstructures. Reports matrix composition of pearlite, ferrite, and graphite. |

| Carbide | Analyze iron carbide (cementite) banding in cast iron. Detects and reports carbide structures relevant to mechanical properties and process control. |

| Settings | Configure ISO/ASTM calibration, report formats, scale bars, default image paths, aspect ratios, and nodularity display settings. Use predefined templates for consistent, error-free workflows. |

| Report & Gallery | Automatically generate, save, and retrieve reports anytime. Organize and access all captured images through Nodularity, Flake, Carbide, and Line Measurement folders. |