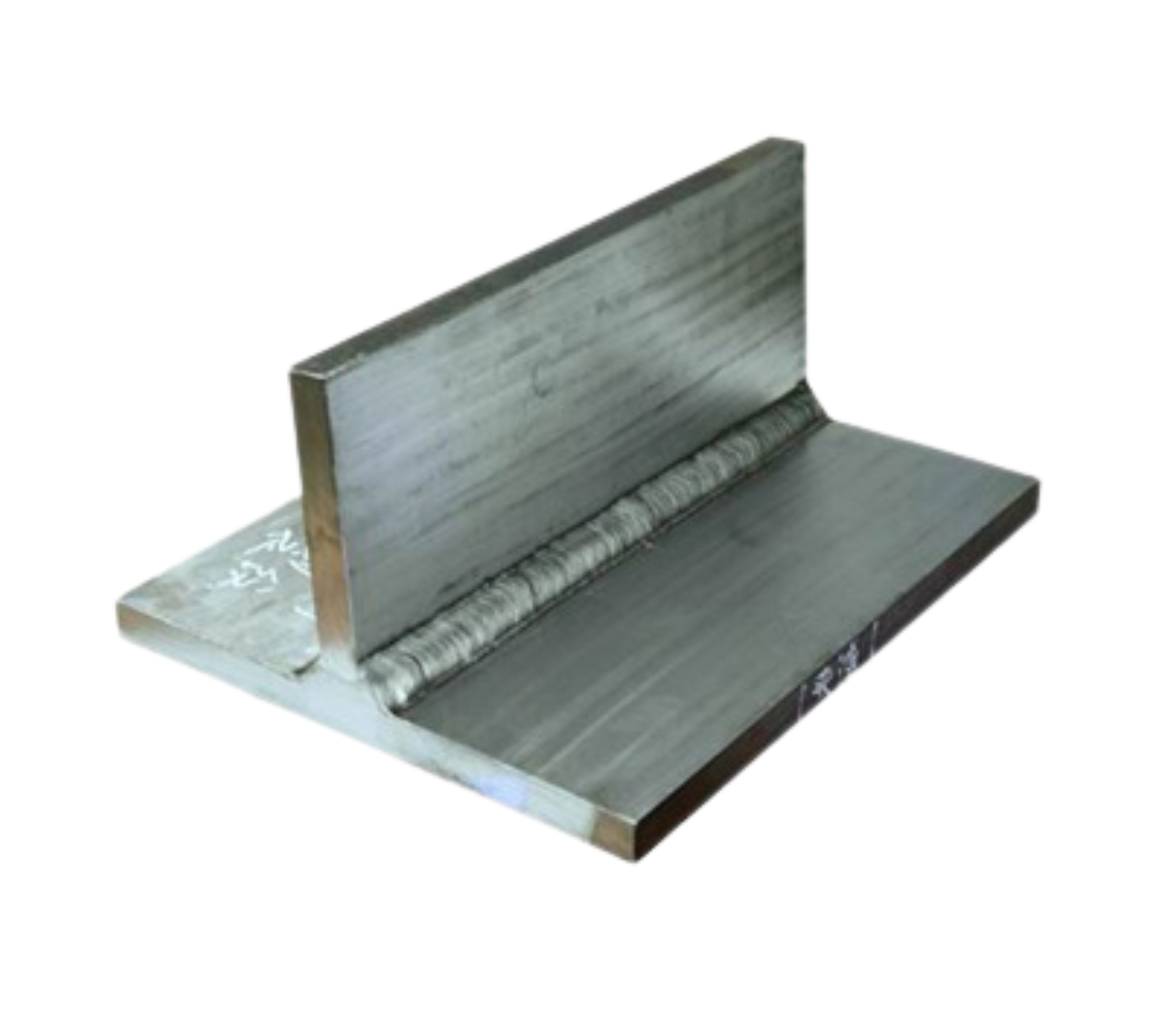

Welded Flawed Specimens are precision-engineered test samples that contain intentional, controlled defects within or around the weld area. Typical flaws include cracks, lack of fusion, porosity, and slag inclusions — closely replicating real-world welding imperfections.

These specimens are vital for Non-Destructive Testing (NDT) applications, offering a practical, realistic way to evaluate inspection procedures, train personnel, validate techniques, and test equipment performance.

At UCOMAX, we specialize in manufacturing high-quality Welded Flawed Specimens designed for practical, reliable Non-Destructive Testing (NDT) training and validation. Each specimen is crafted using premium raw materials free from pre-existing defects and welded with precise, controlled flaws that accurately replicate real-world imperfections such as cracks, porosity, lack of fusion, and slag inclusions. These specimens help ensure inspectors, trainees, and equipment are tested under realistic conditions, supporting certification, procedure validation, and performance checks across industries like refineries, petrochemicals, power plants, and more.

No technical specifications available for this product.